Correct Direction of Track pads

- FarmLife

- 430 crawler

- Posts: 98

- Joined: Tue Aug 28, 2007 8:55 pm

- Location: Saint Clair, Michigan

- Contact:

Correct Direction of Track pads

The 1950 MC we just bought has the 10" regular tracks. The cleat end of the pad is leading but every picture I have seen shows them with the flat leading and then the cleat at the rear. I was wondering which is the correct direction of the cleats and would I just have to take the two bolts out and turn them around or would I just have to pull the tracks and turn them around. Thanks Nate

- switchhappy

- 440 crawler

- Posts: 137

- Joined: Fri Jan 26, 2007 7:24 pm

- Location: bonnieville, ky

Do the pads look like this?

I noticed while browsing the photo gallery that these tracks are different in that the grouser is to the rear. Most tracks the grouser hits the ground first. The main thing to look at is how they overlap, they should be positioned so that dirt tends not to squeeze between pads as they push the machine forward.

I noticed while browsing the photo gallery that these tracks are different in that the grouser is to the rear. Most tracks the grouser hits the ground first. The main thing to look at is how they overlap, they should be positioned so that dirt tends not to squeeze between pads as they push the machine forward.

- emichaelhaynes

- 430 crawler

- Posts: 53

- Joined: Wed May 03, 2006 9:10 pm

- Location: puget sound

pads only go one way on the chain. the two notches fit over the narrow end of the NEXT link.

My machine had one track going one direction and the other opposite and ALL the pads were on backwards. this is the same machine that had the oil pan on backwards and someone torched a new hole in the skid plate rather than turn it around.

I love a challenge

michael

My machine had one track going one direction and the other opposite and ALL the pads were on backwards. this is the same machine that had the oil pan on backwards and someone torched a new hole in the skid plate rather than turn it around.

I love a challenge

michael

Lavoy had posted this reply some time back on the topic.

http://www.jdcrawlers.com/messageboard/ ... .php?t=214

The thing I noticed about the Lindeman pads is they are not the same as a normal grouser shoe as you would see on a later model track system so I can't be much help. Maybe Lavoy can jump in and help straighten this out. If you apply the thinking that Lavoy used in the earlier post and the design of the early pads, it would seem that it you reversed the tracks you'd end up catching rocks under the grouser and bending the pads.

http://www.jdcrawlers.com/messageboard/ ... .php?t=214

The thing I noticed about the Lindeman pads is they are not the same as a normal grouser shoe as you would see on a later model track system so I can't be much help. Maybe Lavoy can jump in and help straighten this out. If you apply the thinking that Lavoy used in the earlier post and the design of the early pads, it would seem that it you reversed the tracks you'd end up catching rocks under the grouser and bending the pads.

Bill Wattson

I should have qualified what I said in the earlier post by saying that this applies only to regular pads, not the pads on MC and BO Lindeman. On those crawlers, the curl goes to the rear like in the picture.

You can just turn your tracks around, no need to go from side to side, the crawler does not know the difference.

Lavoy

You can just turn your tracks around, no need to go from side to side, the crawler does not know the difference.

Lavoy

- Stan Disbrow

- 350 crawler

- Posts: 2898

- Joined: Fri Jul 15, 2005 3:13 pm

- Location: Raleigh, NC

Hi,

If you look closely, you'll see that the Lindemann pads are stamped and have not so much a grouser, but a curl at the extreme end of the pad.

The later (and what we'd call normal these days) pads are forged and have a vertical cleat some distance in from the end.

The curl on the Lindeman pads will pick up last when they come to the sprocket, and give the greastest traction in that direction. If you turned them around, they'd act like little shovels and dig up dirt and drop it all over the sprockets and final drives.

The standard grouser works by pressing down into the dirt, so as far as traction goes, it really cares not which way it's mounted. The things will be pressed into the dirt either way - although they will penetrate more readily if they come down before the rest of the pad given the leverage. They will dig up the ground less if the grouser is laid down first (at the idler) and picked up last (at the sprocket), too.

The real issue we all have when it comes to these things is that we're always looking at them the wrong way. We see them on the top of the chain, where they do nothing at all other than move to the front. Where it really matters ias on the bottom where they meet the ground, and that we can't readily see.

Well, if we *can* readily see the bottom, then we have some pretty serious trouble on our hands!

As long as we're talking about pads, keep in mind that grousers are rough on the chains and rollers. They make things bounce all over the place on hard ground. That's why dozers have tall ones and loaders don't. The thought is that a loader will be much heavier than a dozer, hauling bucket loads of whatnot, and so they get three rows of shorty grouser-like stubs.

Note, too, that many dozers have pads with split-height grousers and big old holes in the center of each pad. These are mud and snow pads and they alternate the height of the grousers to grip mud and snow, and the holes are to allow mud and snow that build up inside the chain links to be pushed out by the sprocket teeth.

Anyway, there's a lot of different pads out there, but those are the main ones.

Stan

If you look closely, you'll see that the Lindemann pads are stamped and have not so much a grouser, but a curl at the extreme end of the pad.

The later (and what we'd call normal these days) pads are forged and have a vertical cleat some distance in from the end.

The curl on the Lindeman pads will pick up last when they come to the sprocket, and give the greastest traction in that direction. If you turned them around, they'd act like little shovels and dig up dirt and drop it all over the sprockets and final drives.

The standard grouser works by pressing down into the dirt, so as far as traction goes, it really cares not which way it's mounted. The things will be pressed into the dirt either way - although they will penetrate more readily if they come down before the rest of the pad given the leverage. They will dig up the ground less if the grouser is laid down first (at the idler) and picked up last (at the sprocket), too.

The real issue we all have when it comes to these things is that we're always looking at them the wrong way. We see them on the top of the chain, where they do nothing at all other than move to the front. Where it really matters ias on the bottom where they meet the ground, and that we can't readily see.

Well, if we *can* readily see the bottom, then we have some pretty serious trouble on our hands!

As long as we're talking about pads, keep in mind that grousers are rough on the chains and rollers. They make things bounce all over the place on hard ground. That's why dozers have tall ones and loaders don't. The thought is that a loader will be much heavier than a dozer, hauling bucket loads of whatnot, and so they get three rows of shorty grouser-like stubs.

Note, too, that many dozers have pads with split-height grousers and big old holes in the center of each pad. These are mud and snow pads and they alternate the height of the grousers to grip mud and snow, and the holes are to allow mud and snow that build up inside the chain links to be pushed out by the sprocket teeth.

Anyway, there's a lot of different pads out there, but those are the main ones.

Stan

There's No Such Thing As A Cheap Crawler!

Useta Have: '58 JD 420c 5-roller w/62 inside blade

Useta Have: '78 JD350C w/6310 outside blade

Useta Have: '68 JD350, '51 Terratrac GT-25

Have: 1950 M, 2005 x495, 2008 5103 (now known as 5045D)

Useta Have: '58 JD 420c 5-roller w/62 inside blade

Useta Have: '78 JD350C w/6310 outside blade

Useta Have: '68 JD350, '51 Terratrac GT-25

Have: 1950 M, 2005 x495, 2008 5103 (now known as 5045D)

Just my 2 pennys.

On the modern pad if you look the grouser is toward the leading edge with the overlap following. This will keep objects from pinching between the pads and bending them.

As far as the difference in loader pads versus dozer pads I was taught that the more agressive the pad i.e. dozer was for torque. The reason they put shorter grousers on loaders is so that you won't develop as mush torque when pushing, your tracks would start spinning first so you don't tear up the loader. The way the loader is mounted versus how a dozer blade is mounted is a big difference. All of the support for loaders are thru a multitude of points. Dozer blades are pretty much stiff armed.

Stretch

On the modern pad if you look the grouser is toward the leading edge with the overlap following. This will keep objects from pinching between the pads and bending them.

As far as the difference in loader pads versus dozer pads I was taught that the more agressive the pad i.e. dozer was for torque. The reason they put shorter grousers on loaders is so that you won't develop as mush torque when pushing, your tracks would start spinning first so you don't tear up the loader. The way the loader is mounted versus how a dozer blade is mounted is a big difference. All of the support for loaders are thru a multitude of points. Dozer blades are pretty much stiff armed.

Stretch

2010C Dozer, 2010C Loader

If at first you don't succeed, get a bigger hammer.

If at first you don't succeed, get a bigger hammer.

Probably the most common reason you see street shoes on a loader is it is more of a multi-surface machine, and they are often used on hard surfaces. A loader with semi-grousers will push about as much as a dozer with grousers in dry conditions due to the extra weight.

One reason I do not recommend grousers on a loader is the increased stress on drivetrain and undercarriage. When a grouser is in the ground and you want to turn, you acutally have to twist the grouser in the ground, and that takes a LOT of power, and puts a lot of stress on trackframes and rails. In the hard clay I have here, I tried turning one time with a 420, 62 blade and 3PT, so it was kind of heavy. It had 14 grousers that were nice and tall, and when I tried to turn, it would kill the engine in 4th gear, not much better in 3rd, and finally had to go to 2nd. Keep in mine, I was not pulling or pushing anything, just turning in the bottom of the ditch which was hard clay sod. The grouser sank in the clay just a little bit, but that was enough to almost prevent the crawler from turning.

Lavoy

One reason I do not recommend grousers on a loader is the increased stress on drivetrain and undercarriage. When a grouser is in the ground and you want to turn, you acutally have to twist the grouser in the ground, and that takes a LOT of power, and puts a lot of stress on trackframes and rails. In the hard clay I have here, I tried turning one time with a 420, 62 blade and 3PT, so it was kind of heavy. It had 14 grousers that were nice and tall, and when I tried to turn, it would kill the engine in 4th gear, not much better in 3rd, and finally had to go to 2nd. Keep in mine, I was not pulling or pushing anything, just turning in the bottom of the ditch which was hard clay sod. The grouser sank in the clay just a little bit, but that was enough to almost prevent the crawler from turning.

Lavoy

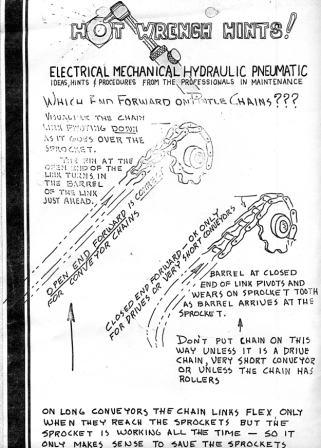

Corret direction of the chain

Hey guys,

No one mentioned the proper way to mount the chains on a sprocket.

I work in a sawmill; according to the maintenance department the open end of the chain should reach the sprocket first.

"The pin at the open end of the link turns in the barrel of the link just ahead." If mounted the other way: "barrel at the closed end of the link pivots and wears on the sprocket tooth as the barrel arrives at the sprocket." (I was going to post a picture of the newsletter, it had pictures and much more explanations, but my brain is fuzzy today and I couldn't get it done.)

Mounting a chain "backwards" on a crawler probably doesn't cause as much excess wear on the sprocket as it would in a sawmill conveyor since the crawler is going backwards part of the time and working in sand and mud. Sprockets are getting hard to come by though, and every little bit helps.

Brian

[/url]

No one mentioned the proper way to mount the chains on a sprocket.

I work in a sawmill; according to the maintenance department the open end of the chain should reach the sprocket first.

"The pin at the open end of the link turns in the barrel of the link just ahead." If mounted the other way: "barrel at the closed end of the link pivots and wears on the sprocket tooth as the barrel arrives at the sprocket." (I was going to post a picture of the newsletter, it had pictures and much more explanations, but my brain is fuzzy today and I couldn't get it done.)

Mounting a chain "backwards" on a crawler probably doesn't cause as much excess wear on the sprocket as it would in a sawmill conveyor since the crawler is going backwards part of the time and working in sand and mud. Sprockets are getting hard to come by though, and every little bit helps.

Brian

[/url]

Corret direction of the chain

Hey,

My brain unfuzzed. Here is the document from maintenance.

You have to think upside down from the pictures in the newsletter.

B.

My brain unfuzzed. Here is the document from maintenance.

You have to think upside down from the pictures in the newsletter.

B.

Who is online

Users browsing this forum: No registered users and 147 guests