Bolt tightness on crawler reassembly

- carolina crawler

- 430 crawler

- Posts: 99

- Joined: Mon Apr 30, 2007 1:51 pm

- Location: marietta ga/marietta sc

Bolt tightness on crawler reassembly

My Question, with all of us restoring these old crawlers, how tight are the nuts and bolts supposed to be..Of all the parts books and diagrams out there, I have yet to see were there is a shop manual that tells you how tight everything is ....since most of the bolts all get loose from time to time...I would think that under carriage bolts/ and power train bolts would not be the same torque as a roller bracket or sprocket or hood cover.I can guess but would rather have some knowledge on how tight everything is supposed to be....thanks..And A Happy New Year to all...Mark/ Cc

- hunter41mag

- 440 crawler

- Posts: 126

- Joined: Tue Apr 12, 2005 7:11 am

- Location: Eastern Pennsylvania (NE of Allentown)

Mark,

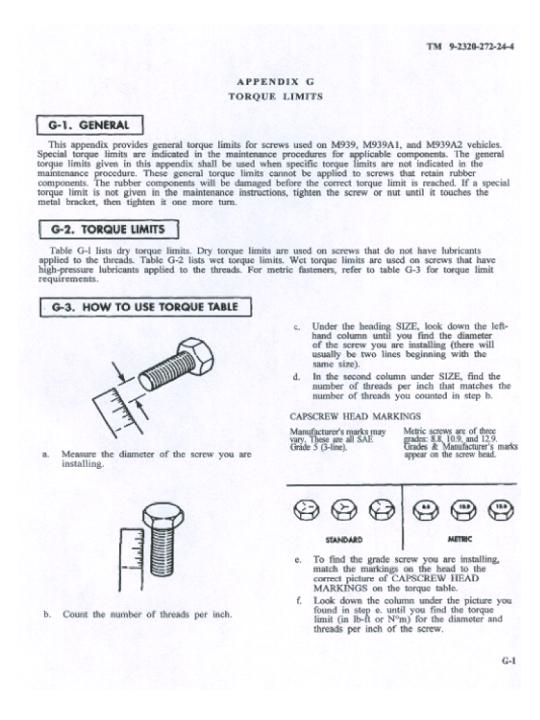

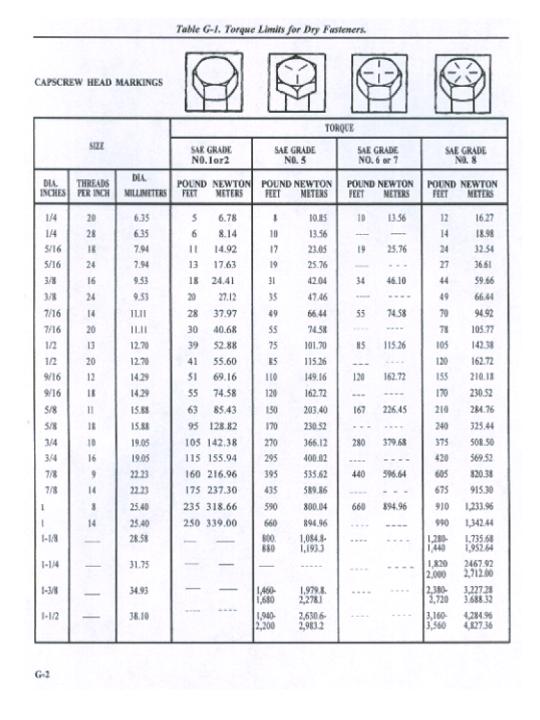

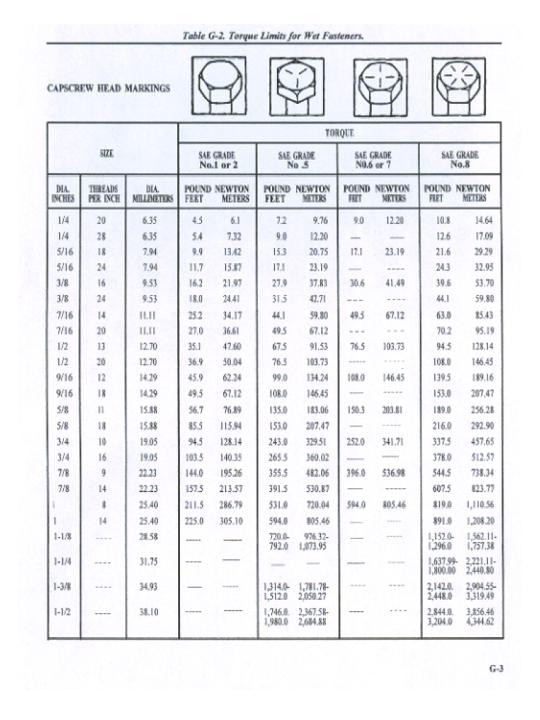

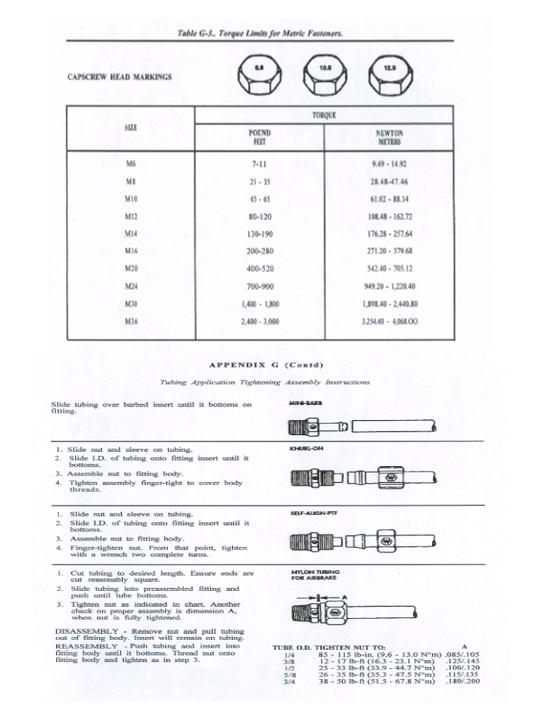

All nuts/bolts have a torque value range. Any special/critical torque values are listed in the OEM service manuals.

You probably will not find torque values in OEM manuals for fender bracket bolts, hood bolts, etc. However they do have a torque value range depending on the grade and size of the nut/bolt. I look these values up in my Mack Trucks Inc "Fastener Torque Value" manual # 1-100. It list the torque value range for most fastener grades and sizes in SAE and Metric.

You can purchase this manual from any Mack dealer or online at "www.macktrucks.com" and then click on "Parts & Service" then "Service" then "Publications" then "Individual Class 8 Service Manuals" then "General Data". Cost is $4 online.

All nuts/bolts have a torque value range. Any special/critical torque values are listed in the OEM service manuals.

You probably will not find torque values in OEM manuals for fender bracket bolts, hood bolts, etc. However they do have a torque value range depending on the grade and size of the nut/bolt. I look these values up in my Mack Trucks Inc "Fastener Torque Value" manual # 1-100. It list the torque value range for most fastener grades and sizes in SAE and Metric.

You can purchase this manual from any Mack dealer or online at "www.macktrucks.com" and then click on "Parts & Service" then "Service" then "Publications" then "Individual Class 8 Service Manuals" then "General Data". Cost is $4 online.

Don

Eastern PA

440IC (1960)

Eastern PA

440IC (1960)

Mark,

If you have any shop manuals laying around look in the back of the manual for torque values. It will be listed by bolt size and torque value. You can also find it on line and print out for future reference. Last resort go by a Fastenal store and pick up a pocket reference.

Just my two cents, but when I am assembling something that has a tendency to work loose I use blue thread locker.

Stretch

If you have any shop manuals laying around look in the back of the manual for torque values. It will be listed by bolt size and torque value. You can also find it on line and print out for future reference. Last resort go by a Fastenal store and pick up a pocket reference.

Just my two cents, but when I am assembling something that has a tendency to work loose I use blue thread locker.

Stretch

2010C Dozer, 2010C Loader

If at first you don't succeed, get a bigger hammer.

If at first you don't succeed, get a bigger hammer.

- thomastractorsvc

- 420 crawler

- Posts: 45

- Joined: Sun Jun 03, 2007 10:07 pm

- Location: Kansas City Area, Missouri

- Contact:

- carolina crawler

- 430 crawler

- Posts: 99

- Joined: Mon Apr 30, 2007 1:51 pm

- Location: marietta ga/marietta sc

God, I love this Job, You guys Rock......I was not sure if the rating was based on the type of bolt/nut configuration or that each item had a certain tightness.... Makes sense , since the thickness of the metal and of the choice of bolts used by Deere during the assembly line process are all similar..(somewhat)..I know the engine would have its own rating, I just was not sure about the rest of the crawler....Whats too tight, and what"s not tight enough.....Thanks so much..all of you......Mark Cc

Who is online

Users browsing this forum: No registered users and 126 guests