Sometimes I hate crawlers

The crawler makes you pay... prove your love

Bartered my baby 420C out all summer to a couple o' giant Norsemen to clear their land so I could get firewood rights to the fallen hardwood. 14 cord was my take. But I worried so much that they would break her. They didn't.

I did. Today! 16'F in the barn and snow on the ground. Started her right up and yanked on the right steering lever. Forced it. Now right steering lever is as flaccid as... (I don't think I'll go there....)

After 5 years, the right (starboard) steering clutch/brake assembly is the last unexplored part of this machine. Not for long. Can't wait for spring so I've got some cold evenings ahead.

It's the getting started that suxs. I'll be obsessed with it soon enough.

Emmett

I did. Today! 16'F in the barn and snow on the ground. Started her right up and yanked on the right steering lever. Forced it. Now right steering lever is as flaccid as... (I don't think I'll go there....)

After 5 years, the right (starboard) steering clutch/brake assembly is the last unexplored part of this machine. Not for long. Can't wait for spring so I've got some cold evenings ahead.

It's the getting started that suxs. I'll be obsessed with it soon enough.

Emmett

420C Crawler 1957 w/ blade & army 6x6 winch

Does sort of remind me of the joke where one guy says he got a new dog for his wife and the other guy replys "I wish I could make a trade like that!"

While I'm still alive, I do have a question. Lavoy, what the H@#$# where you thinking buying another 1010C? Isn't your life interesting enough without dragging another early New Gen crawler home to use up the three remaining parts in existence for the things?

While I'm still alive, I do have a question. Lavoy, what the H@#$# where you thinking buying another 1010C? Isn't your life interesting enough without dragging another early New Gen crawler home to use up the three remaining parts in existence for the things?

Bill Wattson

Bill,

I know, I know, but it followed me home, honest!!!!!!!!!! You know me, if it says John Deere, and is on tracks, so that pretty much does it for me! Part of the incentive was I had just gotten in a week earlier a baby doll of an early 440 with a 91 loader. Planned on re-selling it, walked around it twice, and said no way, it stays. 3 days later, my brother calls and says a life time close friend and neighbor wanted us to find him a crawler loader, so that ended that idea. So, a weeks labor, a bunch of tune-up type parts, and a few bigger parts later, and I have a really nice 440 loader that I won't own in another two days.

Part of the incentive was I had just gotten in a week earlier a baby doll of an early 440 with a 91 loader. Planned on re-selling it, walked around it twice, and said no way, it stays. 3 days later, my brother calls and says a life time close friend and neighbor wanted us to find him a crawler loader, so that ended that idea. So, a weeks labor, a bunch of tune-up type parts, and a few bigger parts later, and I have a really nice 440 loader that I won't own in another two days.

Rob,

The crawler is an early diesel with an inside arm manual 6 way. It has had rails, pads, sprockets and most of the rollers in fairly recent hours, and they must have re-grousered the pads when they did the rest of the undercarriage. The plan was, easy fix (yeah right), spiff it up, and use it for the Winter and/or until I can get my 440 restored, and then sell it again. So, now a weeks worth of labor later, it does have an engine hanging off it again, and that is about it. Hope to light it up next week, and find out how bad I really screwed up. My camera is acting up, if I can get it to work, I will post a pic when it is farther back together.

My camera is acting up, if I can get it to work, I will post a pic when it is farther back together.

Lavoy

I know, I know, but it followed me home, honest!!!!!!!!!! You know me, if it says John Deere, and is on tracks, so that pretty much does it for me!

Rob,

The crawler is an early diesel with an inside arm manual 6 way. It has had rails, pads, sprockets and most of the rollers in fairly recent hours, and they must have re-grousered the pads when they did the rest of the undercarriage. The plan was, easy fix (yeah right), spiff it up, and use it for the Winter and/or until I can get my 440 restored, and then sell it again. So, now a weeks worth of labor later, it does have an engine hanging off it again, and that is about it. Hope to light it up next week, and find out how bad I really screwed up.

Lavoy

Listen Lavoy, it's your obligation to us to take pictures of what you are doing. I have a camera to show people what NOT to do. You need a camera for the opposite reason. Now get busy and do your duty to your readership. As my old boss used to say, "You're being paid exactly what you're worth." That said, I've learned a lot from you.

As my Uncle Bob used to say, "Now go on, git!"

As my Uncle Bob used to say, "Now go on, git!"

2 1010 loaders

1 Massey Ferguson loader backhoe

3 Dodge Power Wagons

1 Wife

3 Kids

1 Massey Ferguson loader backhoe

3 Dodge Power Wagons

1 Wife

3 Kids

Well, unless I get the current problem figured out, the only pic will be of a large fire! Spent most of the day trying to get the injection pump to work. Got fuel all the way to the head, can't seem to get the pump to develop pressure, any pressure whatsoever. Pulled one injector line off at the pump, and not a hint of fuel. Then proceeded to pull what little hair I have left until I gave up and quit. I really wanted to get the engine running without a pump rebuild, thinking more along the lines of bonfire now.  j

j

Lavoy

Lavoy

Lavoy , I know how you feel  , I have been down that road a few times myself when it comes to injection pumps . Sometimes spending money on them is the only cure for what ails them . Like ordering one injection pump for my Lombardini and finding out that they were discontinued two weeks earlier and have to buy three of new style pumps to replace the two good ones and the one bad one

, I have been down that road a few times myself when it comes to injection pumps . Sometimes spending money on them is the only cure for what ails them . Like ordering one injection pump for my Lombardini and finding out that they were discontinued two weeks earlier and have to buy three of new style pumps to replace the two good ones and the one bad one  . $629 to finally find out that the camshaft is worn past its limits and they want another $750 and three to six weeks for delivery .

. $629 to finally find out that the camshaft is worn past its limits and they want another $750 and three to six weeks for delivery .  They do not stock every grind for it here in the U.S. it has to be custom ground in Italy

They do not stock every grind for it here in the U.S. it has to be custom ground in Italy  . But as my sig line says "Used diesel engines are an adventure any way you look at them!!"

. But as my sig line says "Used diesel engines are an adventure any way you look at them!!"

Dan .

Dan .

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

jdemaris

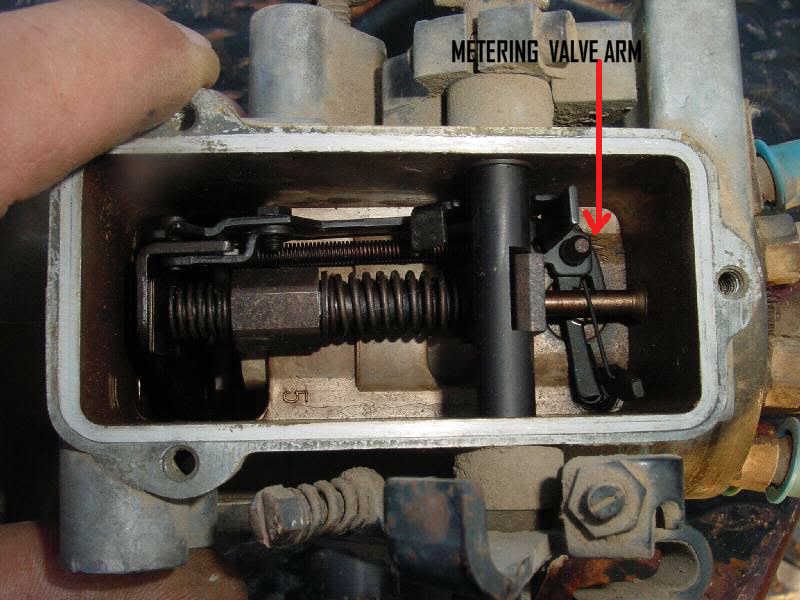

Have you pulled the cover off the pump to make sure the pump is actually turned on? The metering valve - that turns it "on" or "off" sits up high and tends to be the first thing to get stuck in a machine that's been sitting for a long time. When stuck in "off" position, the pump will dribble a little fuel but will not make any pressure. Often, all is needed is to pull the over off and work it loose, by hand. It swivels back and forth. As long as the pump is actually turning - the shear-shaft isn't broken, there isn't much that can stop it from making pressure. There's a little low-pressure fuel pump built into the end of the pump - on top for a 1010. Not much to it - just a vane pump with blades. It sends fuel to the metering valve that I already mentioned. From there, if turned "on", fuel goes to the pump-plungers - then through the delivery valve. So, to not run - either the metering valve must be stuck, the pump plungers, or the delivery valve. As I said, the metering valve is the only component that sits up high and in the open and can dry out over time. The delivery valve also sits up high but it's NOT in the open, it's in a sealed compartment and rarely dries out and gets stuck.Lavoy wrote: Got fuel all the way to the head, can't seem to get the pump to develop pressure, any pressure whatsoever. Lavoy

These photos are of a slightly different model pump - but close enough. Since the 1010 uses a manual shut-off, instead of electric - there's a little C-clip with an ear sticking out - that pushes the metering valve closed for "shut-off." First photo shows the metering valve in "run" position. Second photo shows it in "off" position.

John,

I have fuel to the primary, and if I loosen the cap on the opposite side of the fuel inlet, there is definitely some pressure there when cranking, so I assume the primary is working. I pulled the cover off 3 times last night. There is fuel in that cavity, but I assume that comes from the return line. I wiggled the fuel metering arm several times, and it moves freely. I am assuming that the only motion is like that of a teeter-totter? No fuel after doing this either, that is what has me stumped. I had a very small amount of fuel, just a wiggle at the injector line at the pump once, now nothing.

Two things that I am concerned about, this crawler sat for a dozen years not running, although it ran when parked. The other thing is there is some rust inside the housing on what I assume is the governor arm and spring, like the large one in you pic.

Lavoy

I have fuel to the primary, and if I loosen the cap on the opposite side of the fuel inlet, there is definitely some pressure there when cranking, so I assume the primary is working. I pulled the cover off 3 times last night. There is fuel in that cavity, but I assume that comes from the return line. I wiggled the fuel metering arm several times, and it moves freely. I am assuming that the only motion is like that of a teeter-totter? No fuel after doing this either, that is what has me stumped. I had a very small amount of fuel, just a wiggle at the injector line at the pump once, now nothing.

Two things that I am concerned about, this crawler sat for a dozen years not running, although it ran when parked. The other thing is there is some rust inside the housing on what I assume is the governor arm and spring, like the large one in you pic.

Lavoy

-

jdemaris

Backfeed some air to it

Yes - the metering vavle is just a teeter-totter. If it moves to and fro, it's working. It is just a rotary gate valve for low pressure fuel. I'm going to assume, from what you describe, that the high pressure pump plungers are stuck. That's rare, but can happen if a pump dries out and sits for a long time. Low fuel pressure is supposed to push them out into working position - even 5 PSI will do it. The built-in fuel transfer pump usually cranks at 10 PSI and runs up to 60 PSI when the engine is running. But if they're stuck ?? When they are pushed out like they should be, they ride against a cam-ring, and mechanical pressure from the cam-ramps makes them push back in and make the high-pressure injection stroke. But, if they are stuck, i.e. retracted - it cannot make any pressure.Lavoy wrote:John,

I have fuel to the primary, and if I loosen the cap on the opposite side of the fuel inlet, there is definitely some pressure there when cranking, so I assume the primary is working. I pulled the cover off 3 times last night. There is fuel in that cavity, but I assume that comes from the return line. I wiggled the fuel metering arm several times, and it moves freely. I am assuming that the only motion is like that of a teeter-totter? No fuel after doing this either, that is what has me stumped. I had a veryLavoy

One thing you can try that will work if they are only "lightly" stuck is this. Take an air-nozzle with high pressure air and stick it into one of the injector discharge ports at the pump (the hole that is there, once you disconnect a line and take out the banjo bolt). Then, turn the engine over slowly. At some point, when the pump is in the position to fire on the cylinder you have the air nozzle stuck into - the air will back-feed into the pump and go against those plungers. If you get lucky, you might force them out into working position. By the way, this method is also used to "air time" injection pumps when the timing marks are missing. You can do it with hydraulic pressure too, but sticking an air-nozzle in there is easier. Remember that when those plungers are working they create 2000-3000 PSI easily and are rated up to 10,000 PSI - so you're not going to hurt anything with 125-150 PSI of air.

Okay, the battle continues. I pulled off all four injector lines at the banjoes, left the banjoes on the pump. I put a little but of WD40 on the top of each banjo so I could see if there is any kind of pressure. I pressurized one of the banjoes to about 120PSI with and air hose, and spun the engine. Got a mouthful of WD40 from one of the other banjoes. Did this to all 4, and got a spurt of air/WD40 from one of the other banjoes, and they kind of had a snap to them as they did it. My assumption then is that the high pressure portion is okay, but I am still not getting fuel through the metering valve somehow. Pulled the cover off and wiggled the metering valve again, it moves freely just like before.

I tried pressurizing the inlet side of the primary pump with an air hose to see if I could force some fuel through the blockage (assuming that is the problem), and nothing happened.

At this point, I have to assume that there is something preventing the fuel from getting into the high pressure side. Bonfire is looking better all the time!

Lavoy

I tried pressurizing the inlet side of the primary pump with an air hose to see if I could force some fuel through the blockage (assuming that is the problem), and nothing happened.

At this point, I have to assume that there is something preventing the fuel from getting into the high pressure side. Bonfire is looking better all the time!

Lavoy

Bill,

It still might get melted down, my paitence just did. I give up, it kicked my ass. Finally gave up and pulled the pump a few minutes ago. I really wasn't too enthused about throwing $1000 into a injection pump on a crawler with an unknown engine. But I guess the bring side is if the engine is junk, at least I will have a rebuilt injector pump that is worth half of what I just put into it. I am going to talk to the local pump shop Monday maybe, but I know what they will say, "Leave the pump and $1000 and come back in 3 weeks."

Lavoy

It still might get melted down, my paitence just did. I give up, it kicked my ass. Finally gave up and pulled the pump a few minutes ago. I really wasn't too enthused about throwing $1000 into a injection pump on a crawler with an unknown engine. But I guess the bring side is if the engine is junk, at least I will have a rebuilt injector pump that is worth half of what I just put into it. I am going to talk to the local pump shop Monday maybe, but I know what they will say, "Leave the pump and $1000 and come back in 3 weeks."

Lavoy

If we're talking about Roosemaster, my excellent, overqualified guy here in Connecticut did mine for $600 each along with lapping the injectors or whatever you do to them. I'm happy to represent you for the extra 400. Your friend, Rob (Seriously, I'll call him if you want me to and see what he's up to. I thought he was good. He has an impressive shop and test equipment. He specializes in German pumps. My Roosies were like Model T's compared to his usual fare.)

2 1010 loaders

1 Massey Ferguson loader backhoe

3 Dodge Power Wagons

1 Wife

3 Kids

1 Massey Ferguson loader backhoe

3 Dodge Power Wagons

1 Wife

3 Kids

-

jdemaris

From what you describe, it sounds like the pump is ruined. The head & rotor is the most expensive part of the pump, and many pumps get scrapped once they need one. It is the distributor section of the injection pump and works sort-of like a distributor cap and rotor on a gas engine. It takes the high pressure fuel charge and sends it to the proper cylinder. It does so with a highly poslished, and very tight-fitting rotor that spins inside the head. Basically the rotor has fuel ports that line up with fuel ports in the head (one for each cylinder). It is very touchy and does not work with any wear. Basically, it is either like new - or it is ruined - with very little in-between. They last a long time with good fuel - and can get ruined in seconds if any dirt or water gets in. Also can get ruined from temperature shock.Lavoy wrote: I really wasn't too enthused about throwing $1000 into a injection pump on a crawler with an unknown engine. But I guess the bring side is if the engine is junk, at least I will have a rebuilt injector pump that is worth half of what I just put into it.

If you had a head-port lined up with a rotor port - and when you sprayed air in - it came out freely from other ports - it sounds like you've got a gouge dug into the rotor for it's circumfernece - and if so - it is ruined. Air is not a perfect test since even a good head & rotor will leak a bit with air - but won't leak at all with diesel fuel. When one cylinder is in fire-position, all the others should be completely closed off and sealed.

The first symptom of a bad head & rotor is often an engine that will start cold - but once hot, and shut off, will not restart until it cools down. That's for steady slow wear from thin fuel. Catastrophic wear from water, dirt, or temp-shock is different and can be sudden. That's why the pump has a driveshaft designed to snap in half if the rotor turns too hard.

$1000 would be rediculous to fix that pump unless it is basically ruined and needs a new head & rotor.

The going rate used to be $275-$350 and many shops will still do the pump in that price-range. The vast majority of those pumps need $50 in parts and two hours labor - start to finish, on the bench. If a guy is charging $150 per hour for his time, it still only comes to $350. Not too long ago, the idea was that of a flat-exchange fee. You'd make good money on most pumps, but lose a little on others. It all balanced out. Not any more, from what I've been seeing. Most shops are charging rediculous rates with an exchange - and to add insult-to-injury, void that exchange price if the pump you are turing in has a bad head & rotor.

In the rare occasion that you come across a pump that is actually ruined, with a bad head & rotor, it wouldn't make much sense to buy the new parts - unless absolutely necessary and you needed the pump right away. It's usually cheaper just to find a used pump somewhere that that still turns and fix it instead. Many pump shops do that. They buy cores from junkyards. I've come across many for $100 or less. The head & rotor assembly is the heart of the pump and is just about always reused in a so-called "rebuilt" pump. That because it is so expensive. One exception, however, is the flood of Chinese head & rotors coming around that are half the price of OEM Stanadyne. Not too long ago, a new head & rotor from Stanadyne cost close around $500. Now, I think you can buy a Chinese or Indian untio for $200. I'll also add that even the OEM units from Stanadyne are mostly made overseas now. Last one I bought came from Italy.

I know that places like http://www.dieselcare.com/

charge a flat-rate for Deere DB pumps at $375 if a new head & rotor is NOT needed. So, add to that another $200 and the price ought to be $575-$600 - but you ought to ask first.

Here is how they describe charges for Deere pumps:

"This is a full rebuild that includes new bushings, blades & liner, and all gaskets and seals. These are the items that fail

the most on these injection pump. All pumps are completely disassembled and all parts are inspected.

Please note: Any additional item that has failed in the injection pump other than items listed will be an additional charge.

This is usually not the case, but because we cannot determine whats wrong with your pump without seeing it, so we

have to state that in this ad. You can contact us directly and we can discuss the problem with your unit prior to you

sending it in. "

If you don't already know, you can test a pump - on the bench- by simply squirting diesel fuel into the fuel inlet with an oil-can - and turning the pump with a large screwdriver. No high-tech involved and not air-tight fuel hookup needed. If a pump is good, it will prime itself and start pumping high pressure fuel just by turning it with a screwdriver.

Who is online

Users browsing this forum: Google [Bot] and 87 guests