General help and support for your Lindeman through 2010 John Deere crawler

-

lizrad999

- 430 crawler

- Posts: 59

- Joined: Fri Dec 28, 2007 4:36 pm

- Location: Memphis

-

Contact:

Post

by lizrad999 » Sat Jan 10, 2009 10:42 pm

I spent the day today driving to pickup three sets of tracks for a 420. Gonna make a good set for my 440.

While I was there I picked up a gearmatic winch and adapter plate from the man.

Only problem, is the winch is missing the right cover, and probably some parts ie. clutch etc. The thing definitely runs off of the PTO, so I am looking for a manual and or maybe someone can tell me what model it is.

Appreciate the help!

-

Lavoy

- Site Admin

- Posts: 10943

- Joined: Sun Apr 03, 2005 8:32 pm

- Location: North Dakota

-

Contact:

Post

by Lavoy » Tue Jan 13, 2009 6:05 pm

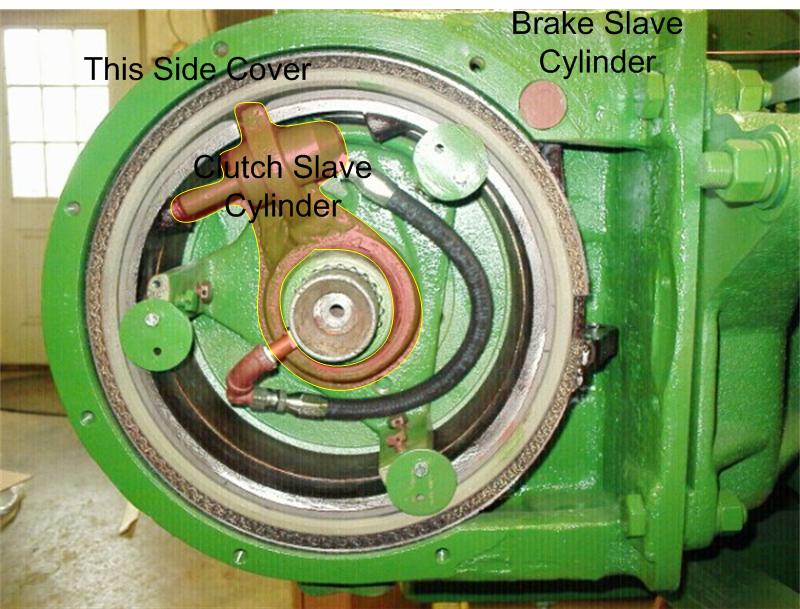

Here is what the inside looks like with most of the parts installed.

Lavoy

-

lizrad999

- 430 crawler

- Posts: 59

- Joined: Fri Dec 28, 2007 4:36 pm

- Location: Memphis

-

Contact:

Post

by lizrad999 » Tue Jan 13, 2009 11:28 pm

Lavoy,

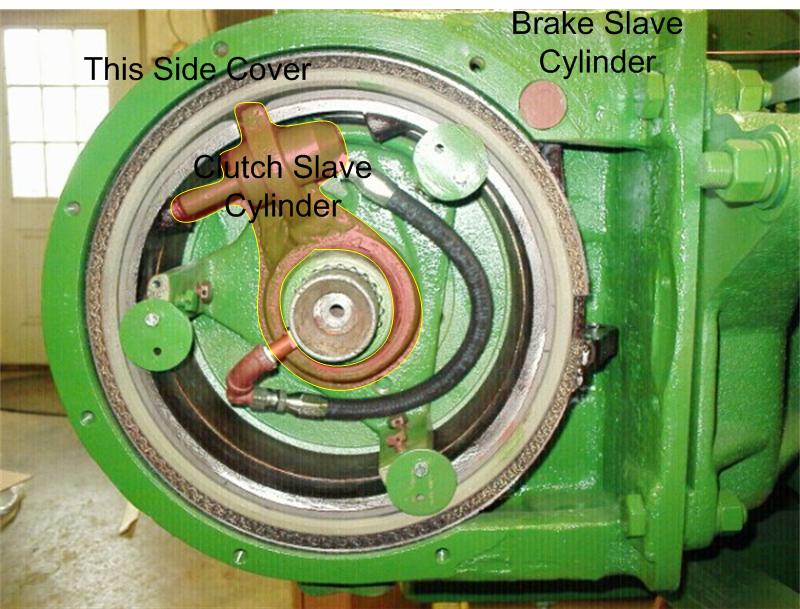

Here is what mine looks like.

-

Lavoy

- Site Admin

- Posts: 10943

- Joined: Sun Apr 03, 2005 8:32 pm

- Location: North Dakota

-

Contact:

Post

by Lavoy » Wed Jan 14, 2009 10:22 am

The biggest problem you will have is the clutch bands, everything else you are missing can be made, or I have it.

Lavoy

-

lizrad999

- 430 crawler

- Posts: 59

- Joined: Fri Dec 28, 2007 4:36 pm

- Location: Memphis

-

Contact:

Post

by lizrad999 » Thu Jan 15, 2009 11:40 pm

Lavoy, do you have the parts I've indicated on your photograph?

Do you know if anyone has ever tried to retrofit some 10" electric trailer brakes to the inside of this in place of the clutch band and hydraulics?

I found another winch that is complete. Fellow said the master control was shot, but he'd take $700 for the lot. Seems kinda high?

"I reject your reality and substitute my own"

-- Adam Savage--

-

Lavoy

- Site Admin

- Posts: 10943

- Joined: Sun Apr 03, 2005 8:32 pm

- Location: North Dakota

-

Contact:

Post

by Lavoy » Fri Jan 16, 2009 10:37 am

The clutch and slave cylinders I have, no side plates left.

Not sure how you would make an electric brake setup work, but doubt it would have enough pull to do anything.

Lavoy

-

Tigerhaze

- 350 crawler

- Posts: 2278

- Joined: Thu Jul 06, 2006 12:13 pm

- Location: West-Central MO

Post

by Tigerhaze » Fri Jan 16, 2009 10:52 am

Some of these brake shops that work on heavy equipment are very good at fabricating bands and such. Have you looked into whether a clutch band could be fabricated given some dimensions or an example they could go by?

(1) JD Straight 450 crawler dozer with manual outside blade; (2) JD 2010 diesel crawler loaders; (1) JD 2010 diesel dozer with hydraulic 6-way blade; (2) Model 50 backhoe attachments, misc. other construction equipment

-

Lavoy

- Site Admin

- Posts: 10943

- Joined: Sun Apr 03, 2005 8:32 pm

- Location: North Dakota

-

Contact:

Post

by Lavoy » Fri Jan 16, 2009 11:09 am

The clutch bands are cast, and have a pocket in the one that the slave cylinder pushed against. It wouldn't really big a big problem to have them rolled out of steel, but I am not sure if they would spring back like the cast one do.

Lavoy

-

lizrad999

- 430 crawler

- Posts: 59

- Joined: Fri Dec 28, 2007 4:36 pm

- Location: Memphis

-

Contact:

Post

by lizrad999 » Fri Jan 16, 2009 11:19 am

Ok, so I'm grasping at straw here....

Lavoy, I can fabricate a cover since I cannot seem to find one, the slave cylinders I will need, so could you PM me a price on those?

As for the clutch band, I found a place that listed that they had them, but when I called him he checked and said all he had was the brake bands. Retail for those was $478. Eek! He said there wasn't enough demand for the clutches to make them. I have no doubt I can find a shop that will work with me to make one or two bands.

We shall see.

"I reject your reality and substitute my own"

-- Adam Savage--

-

Paul Buhler

- 350 crawler

- Posts: 991

- Joined: Wed May 21, 2008 6:25 pm

- Location: Killington, VT

Post

by Paul Buhler » Fri Jan 16, 2009 1:09 pm

Don't forget that the cover needs to have a recess that matches the big (~3") drum bearing, and you'll need the fitting that directs the brake fluid from the winch contol into the inner slave through the cover. Paul

Paul Buhler

Killington, VT

420c 5 roll with 62 blade, FOPS, and Gearmatic 8a winch

-

lizrad999

- 430 crawler

- Posts: 59

- Joined: Fri Dec 28, 2007 4:36 pm

- Location: Memphis

-

Contact:

Post

by lizrad999 » Fri Jan 16, 2009 9:56 pm

This may all be a moot point if I can't get that clutch casting off of the splined shaft!

Right now I've got 10 tons pulling up on those two bolts in the picture while pushing down on the center main shaft, and she is even thinking about moving.

I've soaked it in Tri-flow, PB Blaster, and heated it up three separate times. Shouldn't that piece just slide off of the splines? Or am I missing something here.....

Lavoy, me thinks I might have to cut that thing off......have you got a spare one of them to? I know, I'm getting into the realm of "why bother", but I'm not ready to give up quite yet.

"I reject your reality and substitute my own"

-- Adam Savage--

-

Lavoy

- Site Admin

- Posts: 10943

- Joined: Sun Apr 03, 2005 8:32 pm

- Location: North Dakota

-

Contact:

Post

by Lavoy » Fri Jan 16, 2009 10:00 pm

On the hub, instead of using a puller, use bolts with longer threads, and use them to jack the hub off of the splines. Beg, borrow or steal an rosebud tip for an acetylene torch, and heat all the way around the hub as you tighten the bolts. Once it moves a little bit, then you can switch back to the puller.

Lavoy

-

lizrad999

- 430 crawler

- Posts: 59

- Joined: Fri Dec 28, 2007 4:36 pm

- Location: Memphis

-

Contact:

Post

by lizrad999 » Fri Jan 16, 2009 10:06 pm

I've got a rosebud tip (I knew I'd need one one day!), do I need to get the hub orange hot?

"I reject your reality and substitute my own"

-- Adam Savage--

-

Lavoy

- Site Admin

- Posts: 10943

- Joined: Sun Apr 03, 2005 8:32 pm

- Location: North Dakota

-

Contact:

Post

by Lavoy » Fri Jan 16, 2009 10:08 pm

No, you may not even have to get it glowing. Trick is to heat as much of the outside as you can so it expands uniformlyand lets go of the splines. You may have to get it a dull red, I don't like to get much past that, have distorted stuff in the past.

Lavoy

-

lizrad999

- 430 crawler

- Posts: 59

- Joined: Fri Dec 28, 2007 4:36 pm

- Location: Memphis

-

Contact:

Post

by lizrad999 » Sat Jan 17, 2009 9:19 pm

Once again, Lavoy was correct!

I kept pressure on the hub while I heated it with the rosebud, and before I knew it, it had slid off a little bit. I ended up spending the better part of the day getting the whole thing apart, but I still have all of my fingers and I didn't burn down my house.

Thanks!

"I reject your reality and substitute my own"

-- Adam Savage--

Who is online

Users browsing this forum: No registered users and 52 guests