I have been busy since .......

I have been busy since .......

July the 4th I was working a shutdown at a chemical plant in Erie, Pa. It was a 12hr day. I arrived home to find the power was out and the transformer on the pole had blown. After it was replaced I got to thinking it was time to upgrade the service to the house and shop by going underground and adding a duplex service instead of having the shop run off the breaker panel in the house. After I took a layoff on the 8th of July, I called the PoCo and arranged a meeting to talk to the engineer as to what they wanted for conduit and boxes. I showed him how I wanted to run the conduit from the pole to the house and he made a couple of changes to the route.

The PoCo wanted 3" conduit as I was not running in a straight line from the pole to the house, my route crosses the driveway perpendicular to it instead of running diagonally across it.

The engineer also suggested that I talk to the inspector and find out what he wanted so there would not be any surprises on the day I do the change over.

I started digging on the new service trench on the 13th of July and have made pretty good progress with all the problems , breakdowns and weather delays I have had here.

Some of the breakdowns have included rebuilding the linkages, bins and bushing for my backhoe attachment for my Super-H. Then having a hose blow on the dipper stick cylinder that can only be changed by removing the cylinder from the boom, then having a link in the swing chain break.

As of Sunday I finished the 3" conduit from the power pole and the conduit from the telephone pole to the house and have that all back filled I have some of the 2" conduit in that will feed the shops panel from the rain proof enclosure on the house. I am hoping to do the change over soon and then I can get to work on my shop and rebuild the front part into a machine room to house my lathe, surface grinder and mills, so I can heat it without having to heat the whole shop this winter.

Here are a couple of links to threads I have running on the upgrade and repairs on the backhoe attachment.

Electric Service Thread.

http://www.shopfloortalk.com/forums/sho ... hp?t=30214

Backhoe Repairs.

http://www.shopfloortalk.com/forums/sho ... hp?t=30620

Some of the smaller repairs are in the "Service" thread.

I posted this to update the board to what is going on here.

I have been nervous about doing the sand blasting and other heavy draw repairs with the old service, once I have the services changed over and the shop re-arranged I can get started on the crawler rebuild. Right now I have no room in my shop to do anything but walk through and do machining.

Dan.

The PoCo wanted 3" conduit as I was not running in a straight line from the pole to the house, my route crosses the driveway perpendicular to it instead of running diagonally across it.

The engineer also suggested that I talk to the inspector and find out what he wanted so there would not be any surprises on the day I do the change over.

I started digging on the new service trench on the 13th of July and have made pretty good progress with all the problems , breakdowns and weather delays I have had here.

Some of the breakdowns have included rebuilding the linkages, bins and bushing for my backhoe attachment for my Super-H. Then having a hose blow on the dipper stick cylinder that can only be changed by removing the cylinder from the boom, then having a link in the swing chain break.

As of Sunday I finished the 3" conduit from the power pole and the conduit from the telephone pole to the house and have that all back filled I have some of the 2" conduit in that will feed the shops panel from the rain proof enclosure on the house. I am hoping to do the change over soon and then I can get to work on my shop and rebuild the front part into a machine room to house my lathe, surface grinder and mills, so I can heat it without having to heat the whole shop this winter.

Here are a couple of links to threads I have running on the upgrade and repairs on the backhoe attachment.

Electric Service Thread.

http://www.shopfloortalk.com/forums/sho ... hp?t=30214

Backhoe Repairs.

http://www.shopfloortalk.com/forums/sho ... hp?t=30620

Some of the smaller repairs are in the "Service" thread.

I posted this to update the board to what is going on here.

I have been nervous about doing the sand blasting and other heavy draw repairs with the old service, once I have the services changed over and the shop re-arranged I can get started on the crawler rebuild. Right now I have no room in my shop to do anything but walk through and do machining.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

- Willyr

- 2010 crawler

- Posts: 695

- Joined: Sat Jul 17, 2010 3:03 am

- Location: Downeast Maine (North of Ellsworth)

When we built the new house here. The power goes to the gaqrage and to the house by way of a service line. I dont remember the name of the aluminum wire used (heavy stuff). The garage and house have 200 amp feed. I wired it in so that the power from the meter enters a box, from there it goes to the power interrupt switch (one way is Bangor Hydro service-other way is generator power). Then it branches to house and garage.

As to the trench for the power between the two buildings. I had a well drilled between the two, when the trench was dug for the water line, it shared the conduit. Overkill to have the electric 6' deep. LOL

As to the trench for the power between the two buildings. I had a well drilled between the two, when the trench was dug for the water line, it shared the conduit. Overkill to have the electric 6' deep. LOL

former owner of a 1956 420c

All help is greatly appreciated.

Proud owner of a project 1952 JD 60

http://www.youtube.com/watch?v=nFehqXVd9z4

All help is greatly appreciated.

Proud owner of a project 1952 JD 60

http://www.youtube.com/watch?v=nFehqXVd9z4

I read the shop thread- sounds like the backhoe would break every time you started making progress- I can relate

I'm suprised the co-op cared about your shop wiring- my co-op only cares about underground line to the pad-mounted transformer/meter. Eveything past the meter is my problem. I live in an unzoned county so no pesky county or city inspectors for single family residences.

I'm suprised the co-op cared about your shop wiring- my co-op only cares about underground line to the pad-mounted transformer/meter. Eveything past the meter is my problem. I live in an unzoned county so no pesky county or city inspectors for single family residences.

(1) JD Straight 450 crawler dozer with manual outside blade; (2) JD 2010 diesel crawler loaders; (1) JD 2010 diesel dozer with hydraulic 6-way blade; (2) Model 50 backhoe attachments, misc. other construction equipment

Willy, I thought of adding a switch to transfer to generator power but I can do that later, once I buy the second 200 amp breaker. The rain-proof enclosure has what are called feed through lugs, these lugs are attached to the main buss in the the enclosure. I can use them to connect a generator later.

My well is right next to the trench the 2" conduit is being run in, but the water line does not run underground, it is totally enclosed in the well house.

Dan.

My well is right next to the trench the 2" conduit is being run in, but the water line does not run underground, it is totally enclosed in the well house.

The hoe had lived a rough life before I got it, and was in pretty poor shape. I had been slowly fixing things on it every time I used it before. I knew I would be fixing things while I was digging the trench but did not expect to rebuild the bucket linkage, or be making parts all through this project. I hope everything holds up for the last 40' of trench today(if the rain ever stops), I have to rebuild the swing cylinders and replace the swing chain before I do much more digging with it.Tigerhaze wrote:I read the shop thread- sounds like the backhoe would break every time you started making progress- I can relate

Everything past the meter I own but the Co-op can refuse to connect to a system that is unsafe. The inspector will not inspect anything past the "new" equipment I install. He does want to measure the depth of the conduit at three places along the trench, that is what the drain tile is sticking out of the ground is for. My insurance man told me I could not leave the trench open, even with it taped off, for more than a week, more than a week would require orange snow fence and t-posts to protect it. I talked to the inspector and he said we could dig it up again so he could measure the depth but the pipe would work also. I will suck them out with my shop vac before he gets there so he can see the conduit.Tigerhaze wrote:I'm suprised the co-op cared about your shop wiring- my co-op only cares about underground line to the pad-mounted transformer/meter. Eveything past the meter is my problem. I live in an unzoned county so no pesky county or city inspectors for single family residences.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

My power used to go to the house, then a small underground to the barn. Then I added the two grain bins and the power need was too much for the distance from the house (meter base).

I reran underground from the pole to the barn with a new meter base, then split off two 200 amp breaker boxes, one to feed the house and the other to go to the grain bins. The old meter on the house was replaced with a jumper and glass front.

The electric company supplied me with a new demand meter for the barn. I was not going to use that much juice for that. So when the electrician came over for the final switchover, we used the old house meter on the barn and left the demand meter set on the ground. Needless to say, the electric company was not pleased, but did not switch it out either.

Then we got an ice storm and I hooked up a generator in the barn to feed the house. All I do is switch OFF the main to the house, plug the generator into the welder outlet and there she goes. Separate from the line hookup.

The yard light is wired to the bin side, so when it goes on, I know I have power again from the electric company. I unplug the generator, flip the main back ON and the house is back to normal.

Mark

I reran underground from the pole to the barn with a new meter base, then split off two 200 amp breaker boxes, one to feed the house and the other to go to the grain bins. The old meter on the house was replaced with a jumper and glass front.

The electric company supplied me with a new demand meter for the barn. I was not going to use that much juice for that. So when the electrician came over for the final switchover, we used the old house meter on the barn and left the demand meter set on the ground. Needless to say, the electric company was not pleased, but did not switch it out either.

Then we got an ice storm and I hooked up a generator in the barn to feed the house. All I do is switch OFF the main to the house, plug the generator into the welder outlet and there she goes. Separate from the line hookup.

The yard light is wired to the bin side, so when it goes on, I know I have power again from the electric company. I unplug the generator, flip the main back ON and the house is back to normal.

Mark

JD 2010 Crawler with Loader

Mark, interesting. Once the my new service is up and running, I will start gathering parts to set up a back up generator. Right now I have a small generator that I use to power the TV and the satellite dish.

Yesterday I got the trench dug to the shop and the conduit to within 8' of the shop. Today I have about 4' of trench to dig to make the turn to where the riser has to come up for the shops service panel.

That should not take long to do.

Dan.

Yesterday I got the trench dug to the shop and the conduit to within 8' of the shop. Today I have about 4' of trench to dig to make the turn to where the riser has to come up for the shops service panel.

That should not take long to do.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

The installation of the electrical service conduit is complete I still have to finish the installation of the phone and data conduit from the house to the shop. I need to get a couple of siding mounting blocks before I can run the conduit into the house.

http://www.shopfloortalk.com/forums/sho ... 214&page=9

Dan.

http://www.shopfloortalk.com/forums/sho ... 214&page=9

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Update......

The service tie over is scheduled for Monday, October the 3rd. The PoCo will be here between 8:30 - 9:00am to kill the power, remove the old overhead service and install the new service cable in the 3" conduit.

I plan on pulling the new cable to the shop on Sunday afternoon and then tie it into the shops panel once I have the meter base and rain proof enclosure installed on the house.

I might shoot some video of the whole operation also.

The plan is to cut the mast free from the existing meter box and then remove it, mount the plywood panel, install the two boxes and wire them before the inspector shows up at 1:00pm.

Dan.

I plan on pulling the new cable to the shop on Sunday afternoon and then tie it into the shops panel once I have the meter base and rain proof enclosure installed on the house.

I might shoot some video of the whole operation also.

The plan is to cut the mast free from the existing meter box and then remove it, mount the plywood panel, install the two boxes and wire them before the inspector shows up at 1:00pm.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

The weather today was crappy, but we got the new service to the house done, I still need to install the cable to the shop. But I am going to take a couple of days off from doing that. I need to pump and backfill the last section of open ditch sometime this week and finish moving the compressor into its new temporary building this week. these three links below will take you to the last two posts or the third link is the whole thread.

http://www.shopfloortalk.com/forums/sho ... stcount=99

http://www.shopfloortalk.com/forums/sho ... tcount=100

http://www.shopfloortalk.com/forums/sho ... hp?t=30214

Dan.

http://www.shopfloortalk.com/forums/sho ... stcount=99

http://www.shopfloortalk.com/forums/sho ... tcount=100

http://www.shopfloortalk.com/forums/sho ... hp?t=30214

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

A couple of Photos.

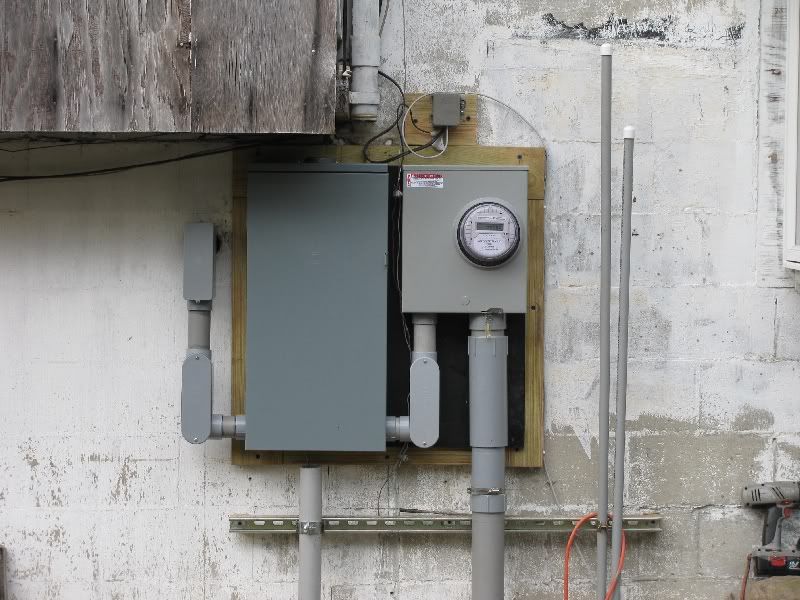

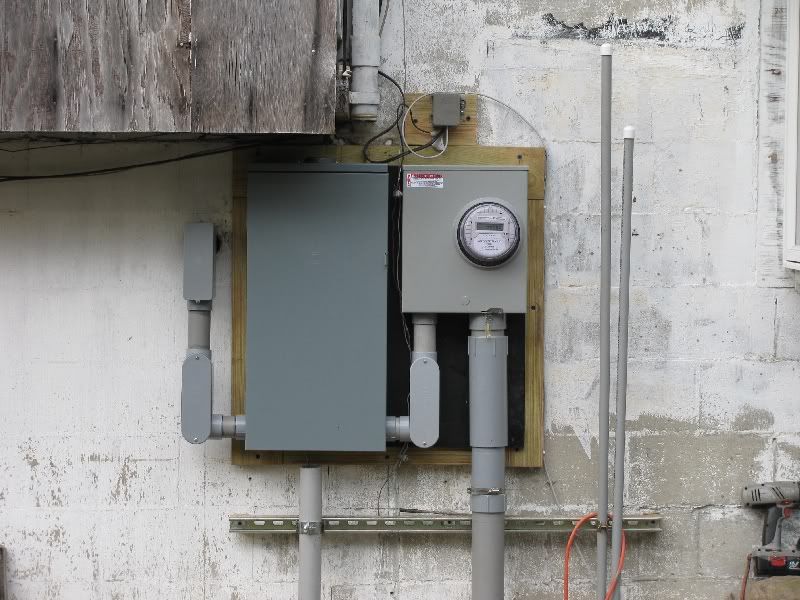

Here are several photos of the old service and the new service.

Old service with new conduits stubbed out.

New service.

Close up.

Overhead service drop gone.

It is kind of strange not to see the overhead service drop there, after seeing it for fifty years.

Dan.

Old service with new conduits stubbed out.

New service.

Close up.

Overhead service drop gone.

It is kind of strange not to see the overhead service drop there, after seeing it for fifty years.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

We are starting to dry out around here finally, I have been working on moving my air compressor, to allow the construction of a new permanent room for the new compressor skid. This project was started last spring and has been delayed by numerous other projects, and acquisitions of machinery for the shop. Once the compressor room and roof rebuild is complete then I will move inside the front of the shop and do the clean out and relocation of the boiler and the inventory that is stored in the shop. Then a new concrete floor will be poured and a double door separating the front of the shop from the rear will be installed and the equipment moved into the new machine area. Then the rear of the shop can be used again as work bays instead of having two mills and a surface grinder taking up that space as it is now.

Dan.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

I will take pictures of the remodel of the shop, as I am doing it.jtrichard wrote:lets see some before and after shop pics?

Today I have to figure out why I can not get the Wisconsin TJD that is on my logsplitter to run.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

I got the splitter running again, it was the carburetor that was preventing it fromshop running. I swapped carburetors with my buzz rig and the splitter fired right up. Then a couple of days later I took the "bad" carburetor apart and found out the floats axle had gotten out of place. It jammed in a nearly closed position. Once the carburetor was back together I installed it on the buzz rig and it now works fine.

I have the rope pulled between the service panel and the shop and I am waiting to get a dry day to pull the temporary service cable to the shop.

A buddy had a some 3/0 cable leftover from a job he was on and suggested I use it until I can buy the 4/0 for the new service.

I really do not want to be fighting with cold 4/0 aluminum cable.

Dan.

I have the rope pulled between the service panel and the shop and I am waiting to get a dry day to pull the temporary service cable to the shop.

A buddy had a some 3/0 cable leftover from a job he was on and suggested I use it until I can buy the 4/0 for the new service.

I really do not want to be fighting with cold 4/0 aluminum cable.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Who is online

Users browsing this forum: No registered users and 94 guests