Discuss non-crawler related issues here (keep it sane, please)

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Fri Mar 30, 2012 8:10 pm

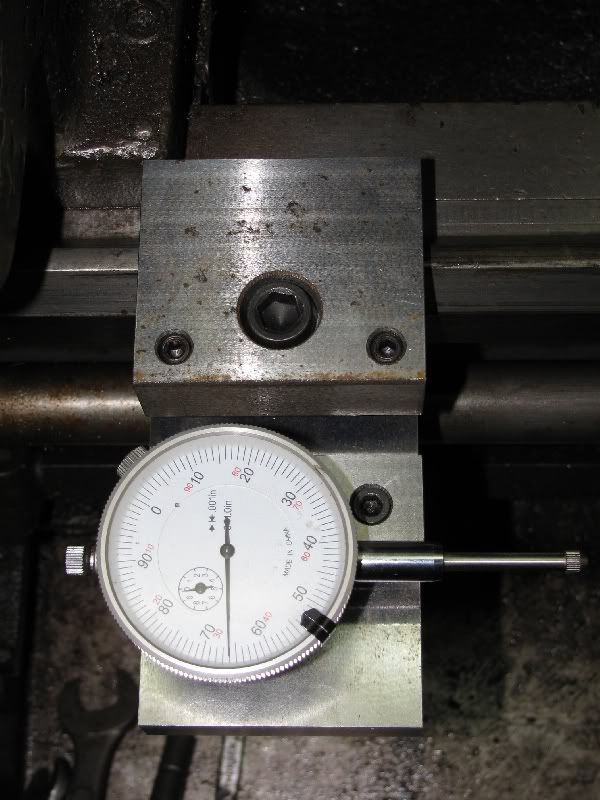

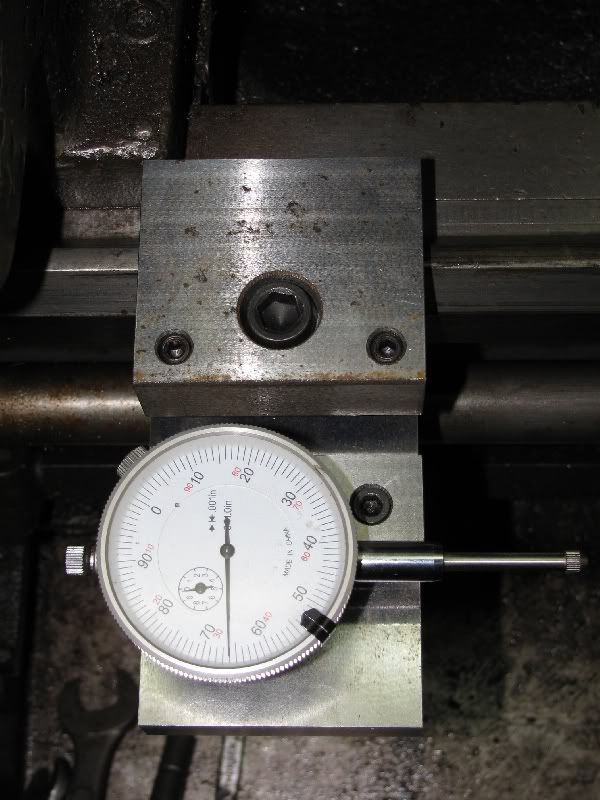

I started making a fixture for mounting a dial indicator to the trapezoidal my lathe.

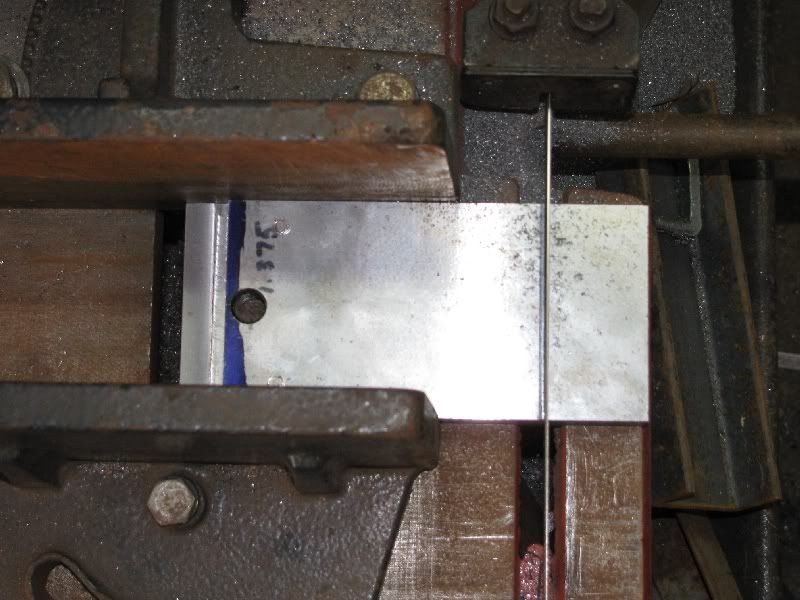

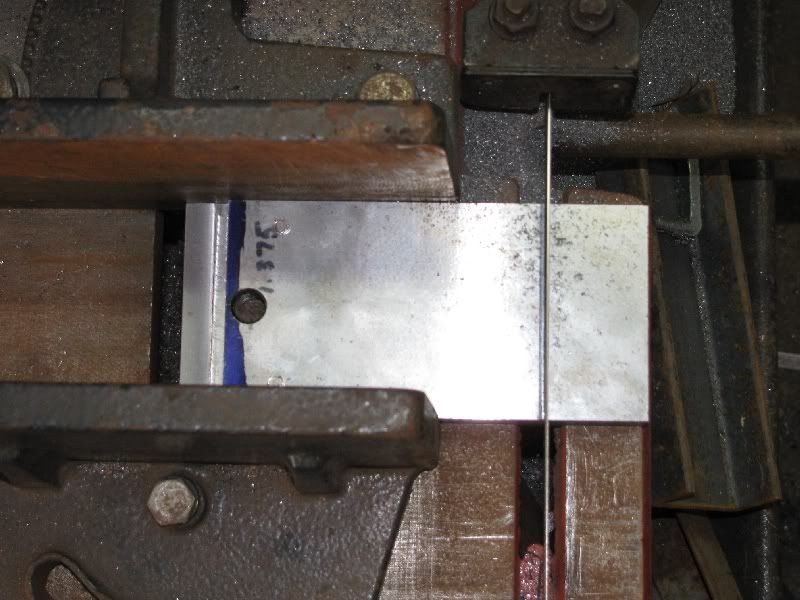

Cutting the stock for the clamp

Stock squared up, ground and slot laid out.

Relief slot milled into the clamp, the relief slot is to allow for clearance on the top of the way.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Fri Mar 30, 2012 8:38 pm

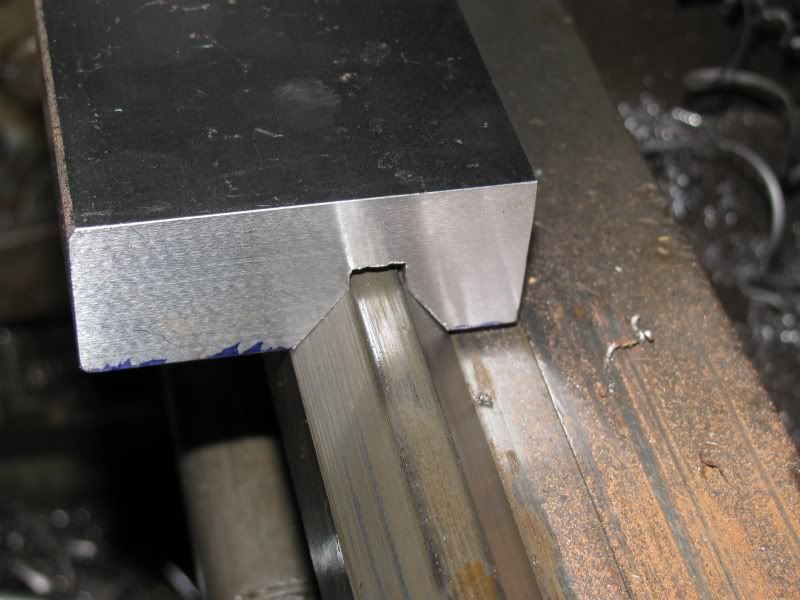

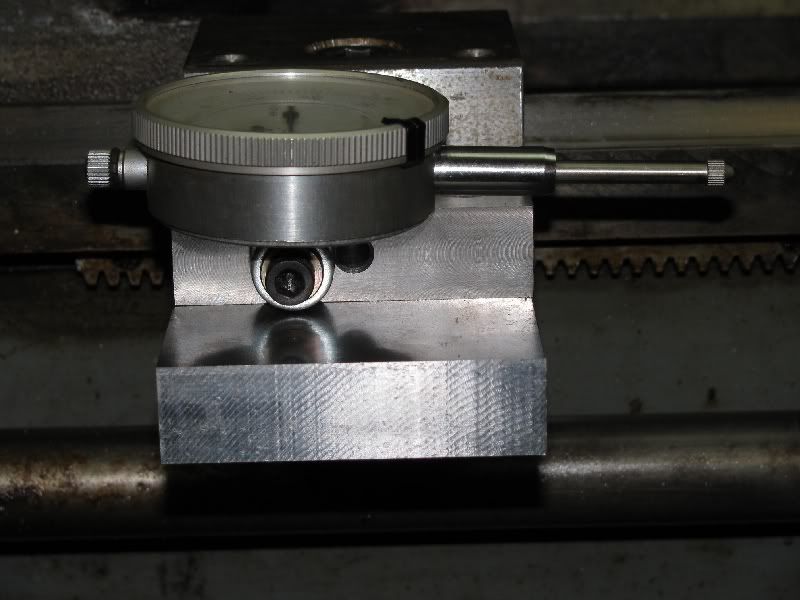

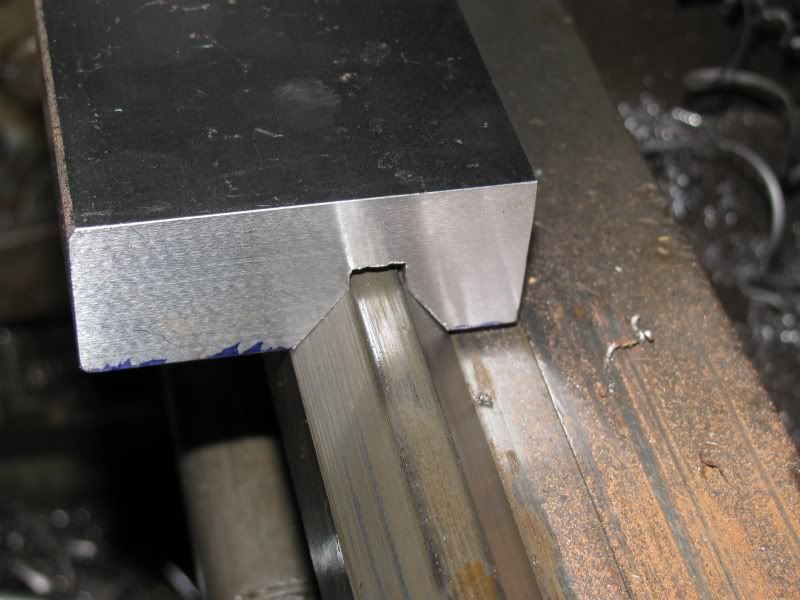

The next step was to cut the angles to match the way. This involved setting the block up in the mill at 35°, and then taking cuts off one of the corners. Since the two angles add up to 70°, you also have to trim the opposite corner of the groove to provide clearance to cut the groove to the proper depth. Once I had both angles cut I test fit it to the v-way.

Fits pretty good.

Close up.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Fri Mar 30, 2012 8:44 pm

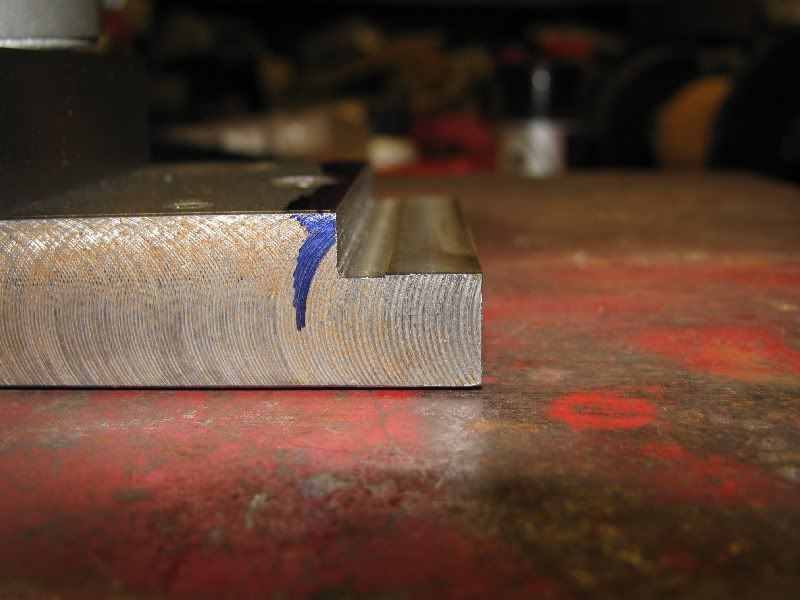

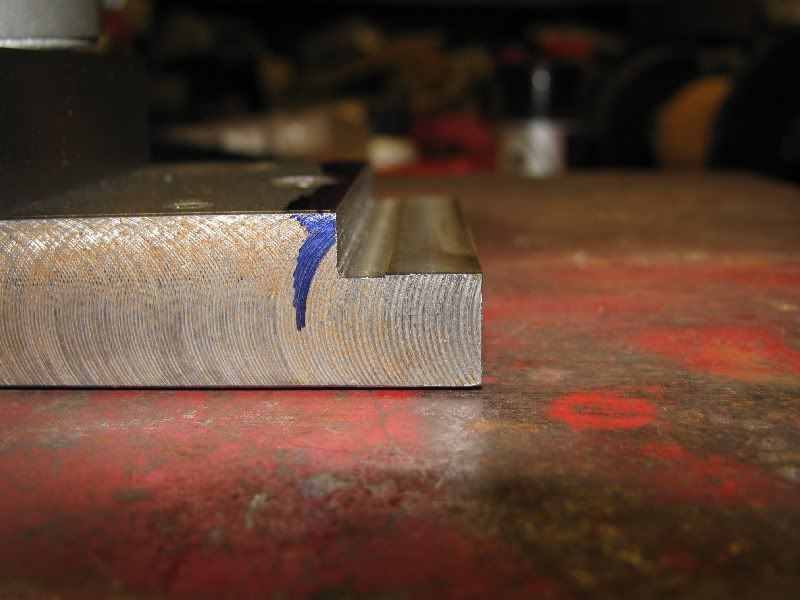

Close up pictures of the groove.

I will have to grind the faces of the angles to remove the tool marks on them.

Dan

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Tue Apr 24, 2012 1:12 pm

I did finish up this project last week, and had to jump to another project

So here are the photos of the rest of this one.

Clamp finished.

Ready to locate and drill a 25/64" hole to tap at 7/16" - 20

The clamp and base assembled.

Ready to cut off the excess steel.

I used the drop piece to make the block that the Indicator mounts to.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Tue Apr 24, 2012 2:50 pm

I had to mill the block down to 3/4" X 3/4", I then drilled two holes to bolt it to the base.

Test fitting the block.

Block bolted down, indicator mounted and ready to be assembled.

I milled a step into the end of the mount to help with alignment.

Finished mount.

Another view.

I have to drill and tap for a stop bolt before I paint the assembly.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Mon May 07, 2012 6:09 am

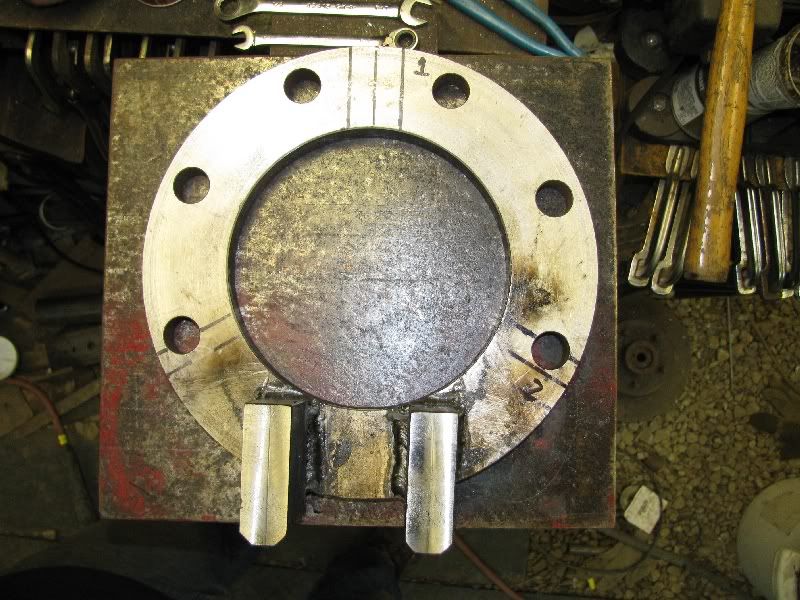

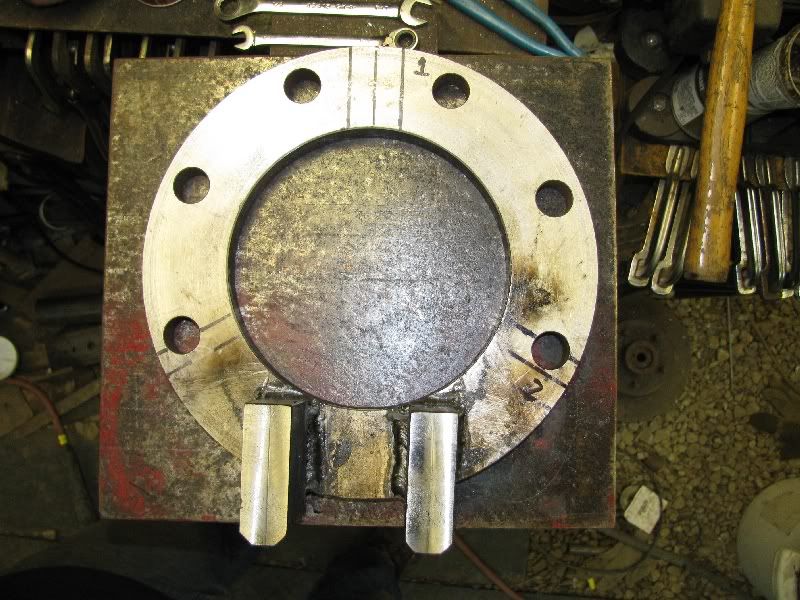

Steady Rest

The start of the steady rest, this flange is a 6" 150# RF Slip-on flange, it was just tacked to the pipe.

The backside of the flange.

The shoulder removed and the flange cleaned up.

Cleaning up the face, the RF above in the description of the flange stands for raised face. that means the sealing face is about 1/16" higher then the rest of the face.

Now the flange is a ring, 7/8" thick. 11" in diameter with an ID of 6-3/4"

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Mon May 07, 2012 6:15 am

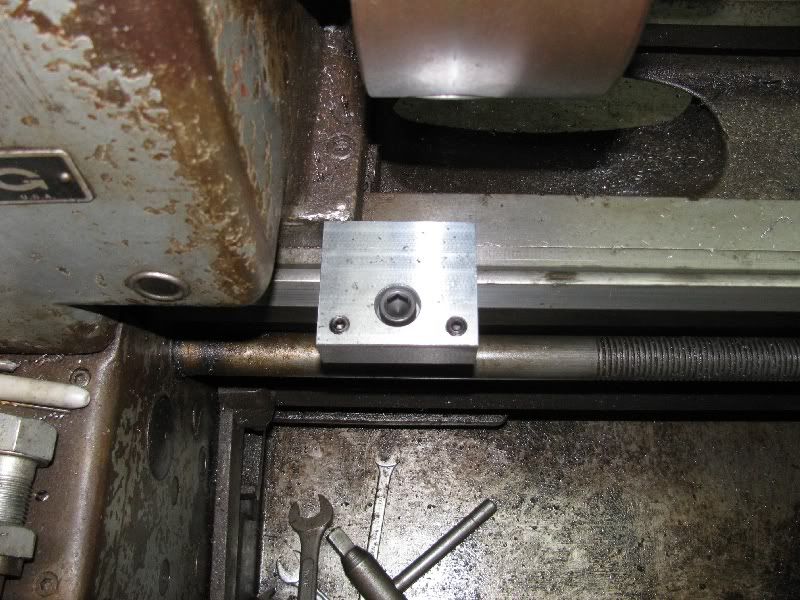

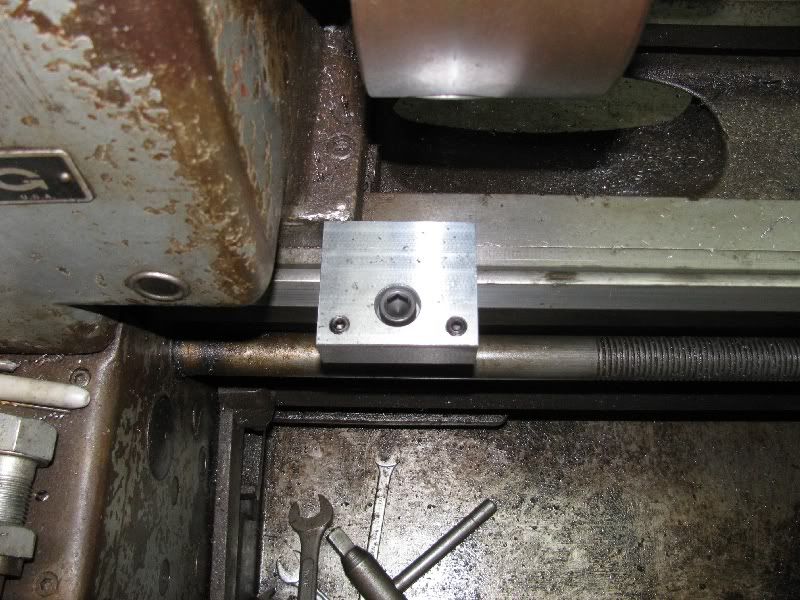

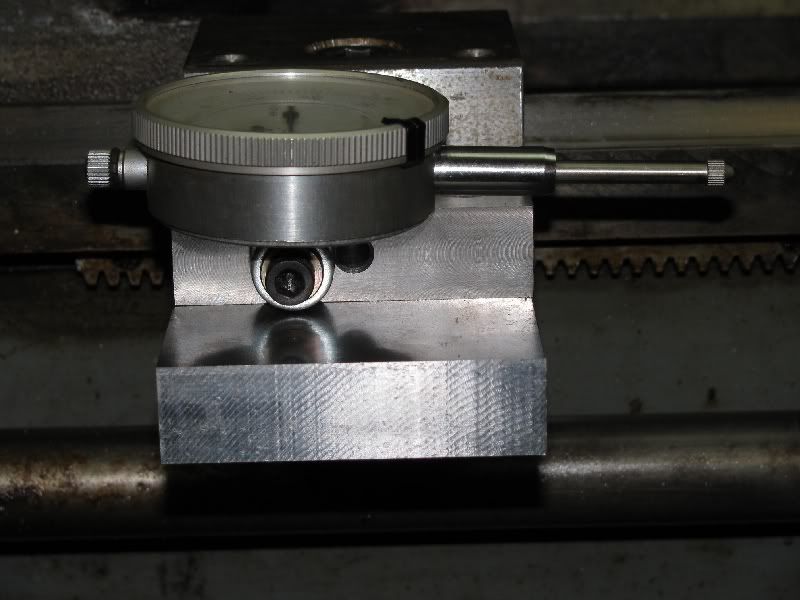

The base machined and test fit.

The base aligned as it will be in the final product.

The clamp block. I milled steps into the end of the clamping block to help align it to the bed ways.

The base with the bolt slot milled into it.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

andregrondin

- 440 crawler

- Posts: 215

- Joined: Mon Apr 18, 2011 6:51 am

- Location: Granby,Québec, Canada

Post

by andregrondin » Mon May 07, 2012 6:25 am

HI !

That is great machinist work !!

Dig in boy !!

J-D 350 straight 1966

model # = T4F3D

serial # = 08883T

J-D 690-B 1980

model # = D690B

serial # = 007364T

Mack RB688S 1990 dumper

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Mon May 07, 2012 6:25 am

One of the two stands with the edges beveled.

Ring with the position of the stands laid out.

The stands ready to clamp to the ring and the base plate.

Clamped up ready to weld.

Welded up.

I will be working on the arms or fingers today.

Once this is finished I will give it a good sandblasting to remove the the welding smoke stains and give it an even finish before I paint it.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Mon May 07, 2012 6:34 am

andregrondin wrote:HI !

That is great machinist work !!

Andre, thanks. I trained as a Tool & Die Maker but never pursued it as a career. I could not stand at a machine all day now for sure. I have to break up the machining jobs into sections, so I do not get too bored watching the lathe run. The mill and surface grinder are easier to spend time on as they require operator input to function correctly.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Mon May 07, 2012 8:21 pm

Here are pictures of today's progress.

Tubes cut to 4-1/16" for test fitting of them to check clearances.

The tubes clear the carriage my a large amount, so I can make my hand wheel in the 2" range.

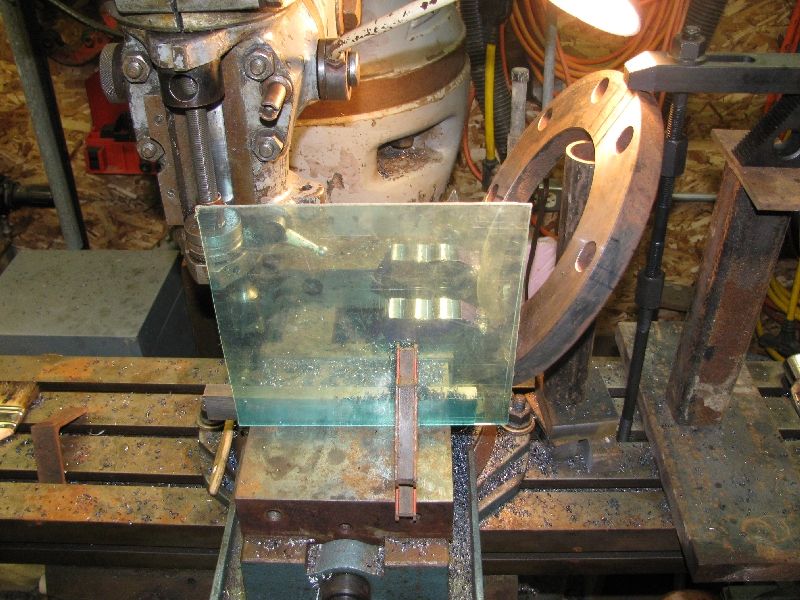

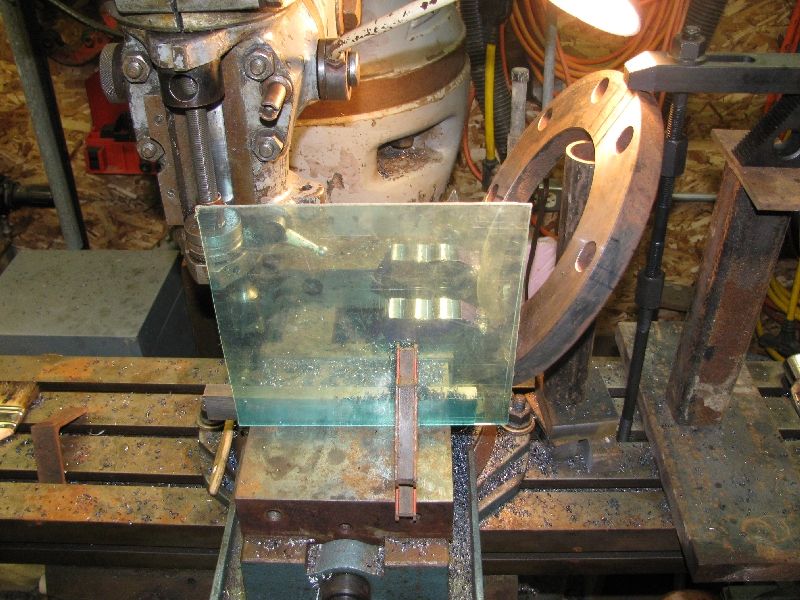

Set up to mill a 30° angle on the top of the stands.

Milling in progress.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Mon May 07, 2012 8:26 pm

More photos.

Milling complete.

The set up.

Milling the angle on the two stands was done so I could get the steady rest as close to the chuck as safely possible.

Ready to start machining the pieces for the telescopic arms.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

andregrondin

- 440 crawler

- Posts: 215

- Joined: Mon Apr 18, 2011 6:51 am

- Location: Granby,Québec, Canada

Post

by andregrondin » Tue May 08, 2012 5:44 am

Hi !

great work I love when people are making there own tools .

Dig in boy !!

J-D 350 straight 1966

model # = T4F3D

serial # = 08883T

J-D 690-B 1980

model # = D690B

serial # = 007364T

Mack RB688S 1990 dumper

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Tue May 08, 2012 9:52 pm

Andre, making my own tools is a lot easier than it use to be!

The rain that had been holding up a couple of other projects, let up around noon today. So I finished cutting up an old truck that pieces of it will live on in another project of mine. I had the rest of that truck two old trailer and a front suspension from another truck to cut up and send to the scrapyard today.

I saved the pieces I needed and the rest of them will go to the scrapyard in the morning. I still have the front suspension from the first truck to cut up in the morning as I had to pull the engine out of it before I could cut it up. I just plumb ran out of light to cut by tonight.

I saved the rear axle out of the truck to get the spindles and axle tubes out of it for the project in this link.

http://www.shopfloortalk.com/forums/sho ... php?t=6677

I have been gathering parts and pieces and the machine tools to build it for about six years.

The steady rest will be an integral part of the machining of the axles for that project.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

-

Lu47Dan

- 1010 crawler

- Posts: 401

- Joined: Mon Feb 11, 2008 3:17 pm

- Location: NWPa

Post

by Lu47Dan » Thu May 10, 2012 8:43 pm

I got the final materials for this project today, a 3' piece of 3/8" threaded rod and a 4' piece of 1 X 1 tube to make the telescoping arms.

I might get a 7/16" - 14 tap and go bigger with the threaded rod, instead of the 3/8" rod.

Dan.

1956 420C with GSC blade

Tools are to men as shoes are to women , you can never have too many !!

Used diesel engines are an adventure any way you look at them !!

Who is online

Users browsing this forum: No registered users and 97 guests