1010 flangede axle weld repair

1010 flangede axle weld repair

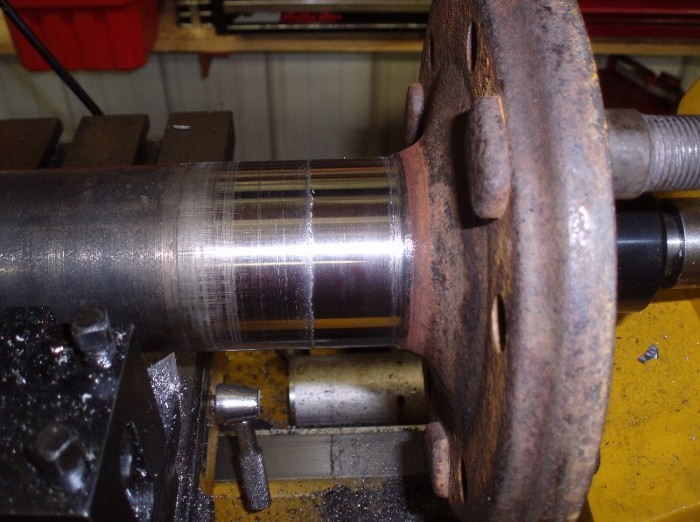

[ims]http://www.jdcrawlers.com/uploads/p1010 ... ed__31.jpg[/img][url] After much thought and consulting I decided to use GTAW(tig ) with 309L ss filler metal. ESAB rep recommended powder spray but we concluded my model B torch was too small for the size of the shaft. His next choice was GTAW using a 300degree F mininum pre heat. He belives that the axle is probably 4130 material. It took two passes to fill up the groove and give me .070 extra to machine down. As the gold and purple colors indicate the heat input was kept to a minimum. The 309L wire welded smooth with no fusion issues. I used 3/32" filler. Had some 1/8" but chose the smaller to keep the heat input down.

I wrapped it in rock wool insulation and placed it on top of my old moores gas heater which was at about 250 degrees f. I then shut off the heater and let it cool to ambient temperature. I started to machine the axle tonight. Using 200rpm and a very slow speed and a cut depth of between 0.002" and 0.004" I am achieving a reasonably smooth finish. No coolant used. Hope to perfect the machining before I get it turned all the way down to size, but if the finish is no better than I am achieving presently a lite sanding should do the trick. Mark

Completed the od build up on the axle shafts. As I mentioned before I used 309L filler metal. Should stop any corrosion even if the seal area has retained dirt/moisture. I chose not to mess with the area where the beareing race will ride as my machining skills are limited. The fusion line left is in the space between the race and the seal and will have no bearing on the operation of either. I found the key to machining the SS material was slow rpm(200) and a lite cut(0.0002") for the last couple thousands. Have assembled and installed one final with no issues and am working on the second. Mark

Completed the od build up on the axle shafts. As I mentioned before I used 309L filler metal. Should stop any corrosion even if the seal area has retained dirt/moisture. I chose not to mess with the area where the beareing race will ride as my machining skills are limited. The fusion line left is in the space between the race and the seal and will have no bearing on the operation of either. I found the key to machining the SS material was slow rpm(200) and a lite cut(0.0002") for the last couple thousands. Have assembled and installed one final with no issues and am working on the second. MarkWho is online

Users browsing this forum: No registered users and 55 guests

[/img]

[/img]