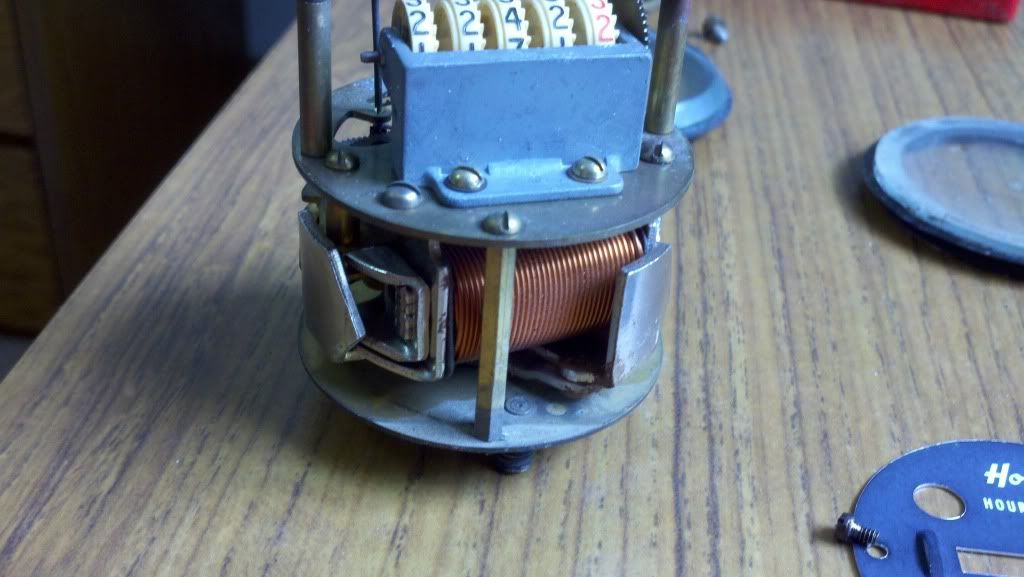

Worked on the hour meter over the weekend. I was going to use the original meter because it still worked good, but the face was in rough shape. I located a second one that only worked intermittently, so I took both apart. I was pretty surprised at what I found. It turns out that there is a set of contacts, and when they close it applies power to the coil. When the coil has power the magnetic field moves and arm which "winds up" the meter. When this happens the contact opens and the meter counts. After about 1 min. the counter has wound down and the contact closes and it winds up again if there's power applied from the oil pressure switch. Pretty neat actually.

Anyway, I oiled up the newer meter and it is working much better now so I decided to use it. Also the contact on my original meter is burnt and worn pretty badly.

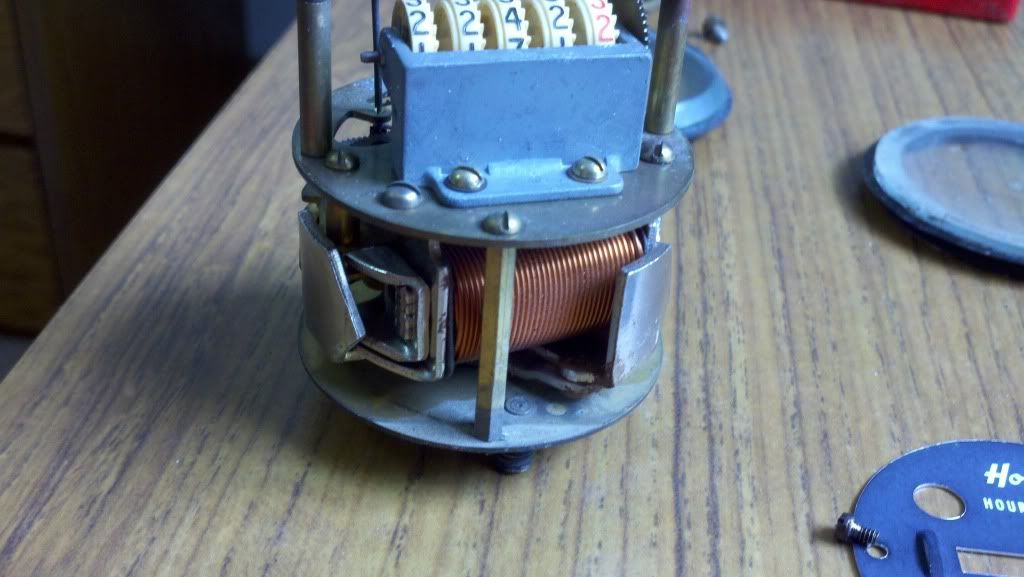

Coil and arm that "winds meter."

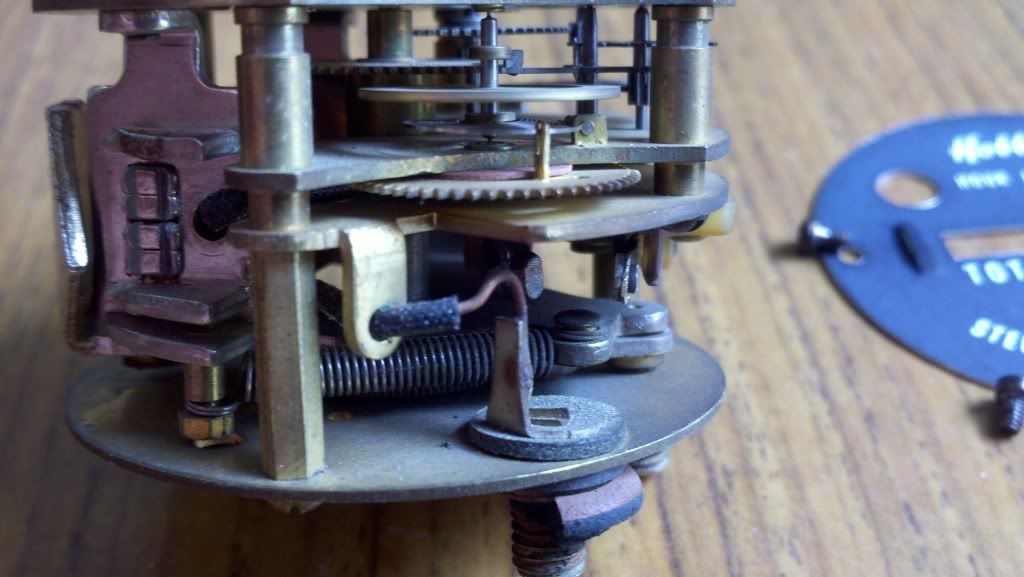

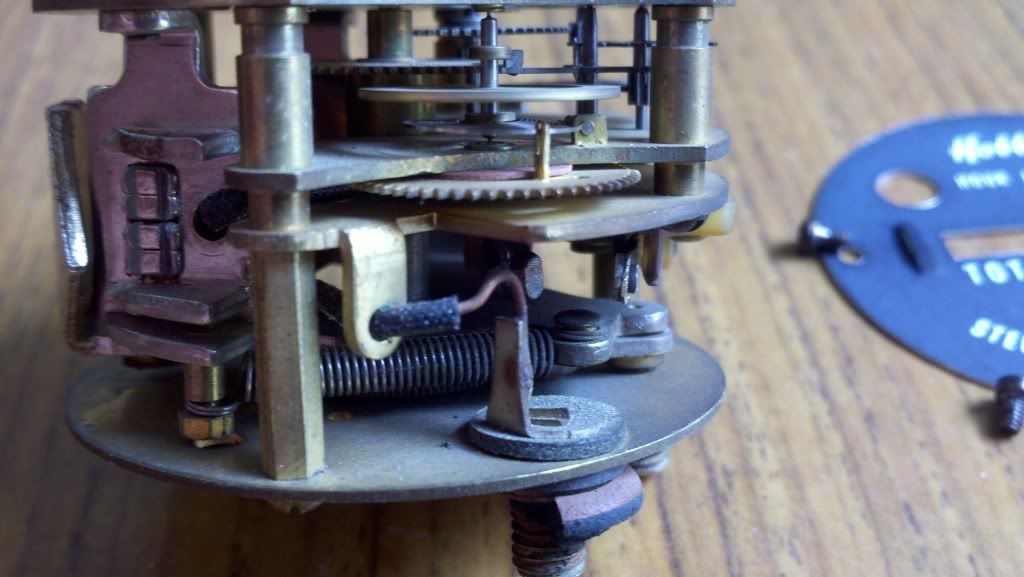

Contact (shown in open position). This is on my meter, badly worn.

Date stamp on my original hour meter

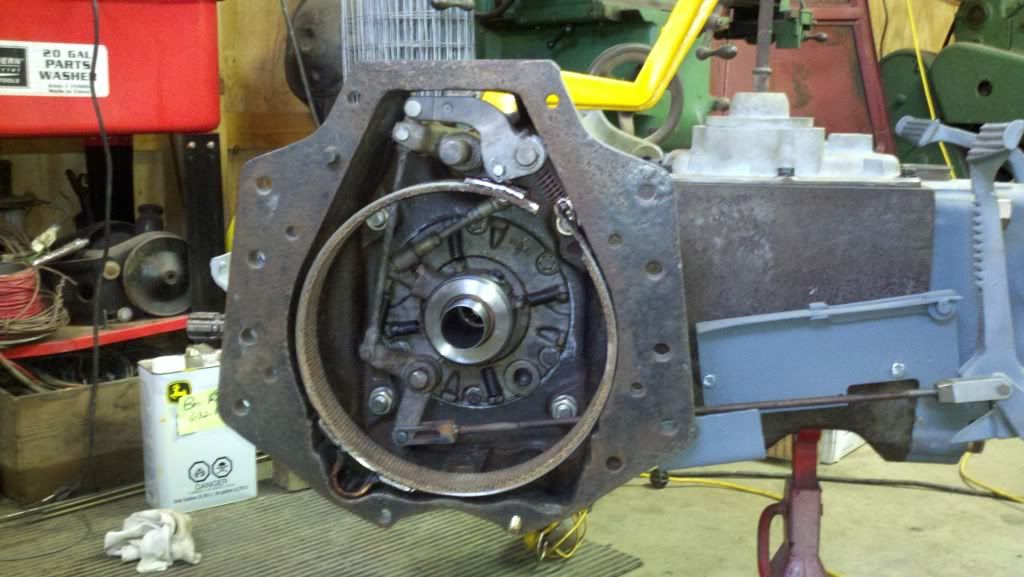

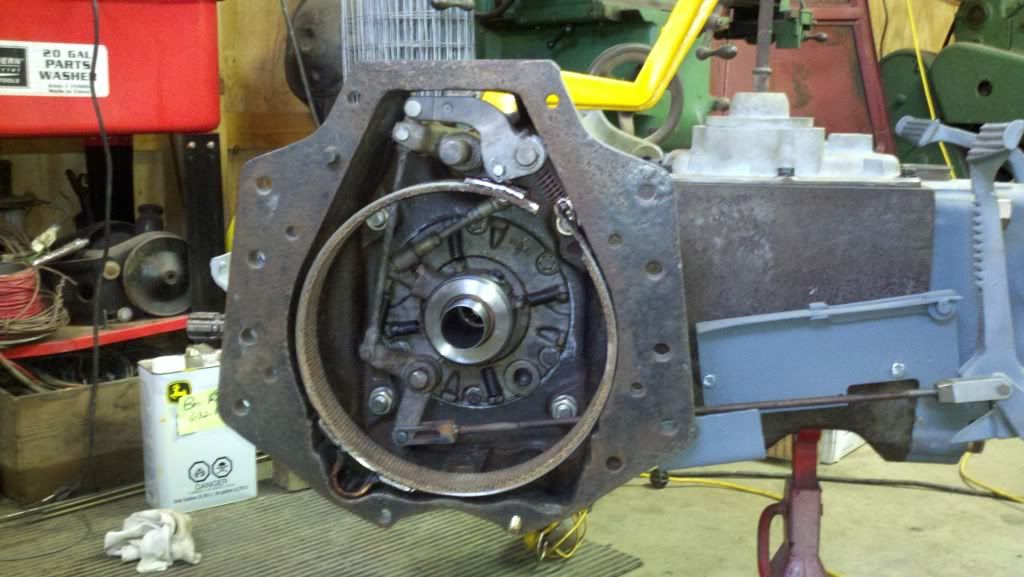

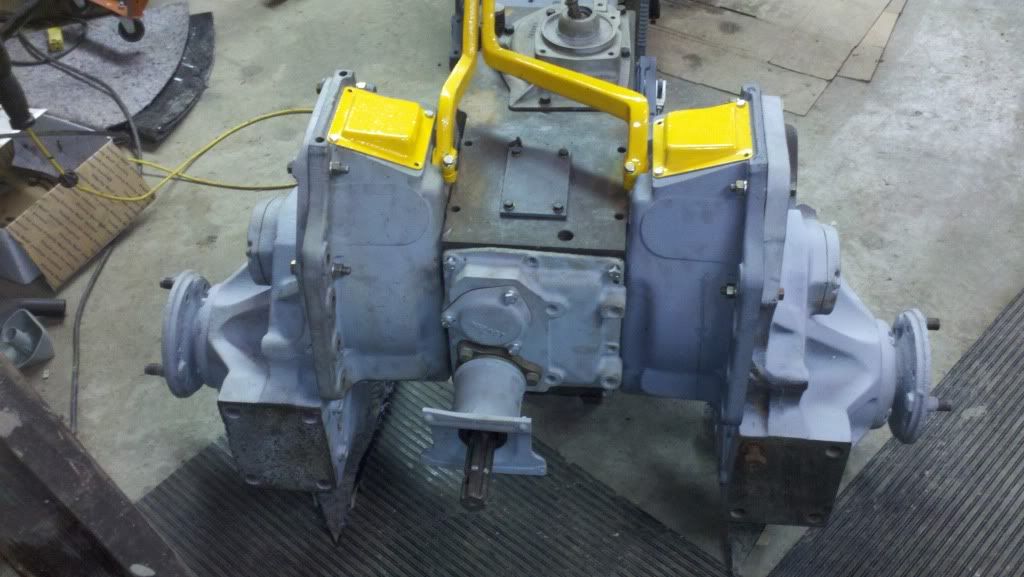

Rock Guards I've been working on.