Thought I would post here as well as HEF. https://www.heavyequipmentforums.com/th ... 50c.82848/

Background story, I picked this old girl up for free about a year ago. Sitting in a field, hadn't ran for 3/4 years. Fixing her up to sell, maybe keep around the farm for a little bit to play with.

Here is a Youtube video I put together of essentially part #1. Right now I am close to having the machine back together, kind of

https://www.youtube.com/watch?v=2haIkpVmIuk

-------------------------------------------------------------------------------------------------------------------

STATUS UPDATE:

1) Engine oil pan gasket replaced

2) Front hydraulic pump return and supply lines removed, cleaned, replaced sections as needed

3) Trans sump screen filter element removed, cleaned, new o-rings and gasket installed. Rewired the pyro for the trans (wire was just cut)

4) Fuel tank removed, cleaned, pressure tested, and re-sealed with "Red Kote" and reinstalled

5) Radiator re-cored, hydraulic cooler cleaned, pressure tested, painted for looks core was good. Reinstalled

6) New air filter, fuel filter, engine oil filter, and both hydraulic filters replaced (front trans and in tank)

7) All new hydraulic lines (boom, angle, and tilt cylinders)

8 Re-built tilt cylinder (barrel re-honed, piston polished, seals, packings, etc.)

9) New water pump gaskets (backing plate and pump gasket), new thermostat and gaskets (head and thermostat housing)

10) New v-belt

11) New upper and lower radiator hoses

12) New exhaust manifold and gaskets

13) New Turbo (Airesearch AR70439)

14) New "adapter" for turbo to exhaust

15) New seat back/bottom and armrests

Still lots left to do before I put it up for sale.

----------------------------------------------------------------------------------------

QUESTIONS:

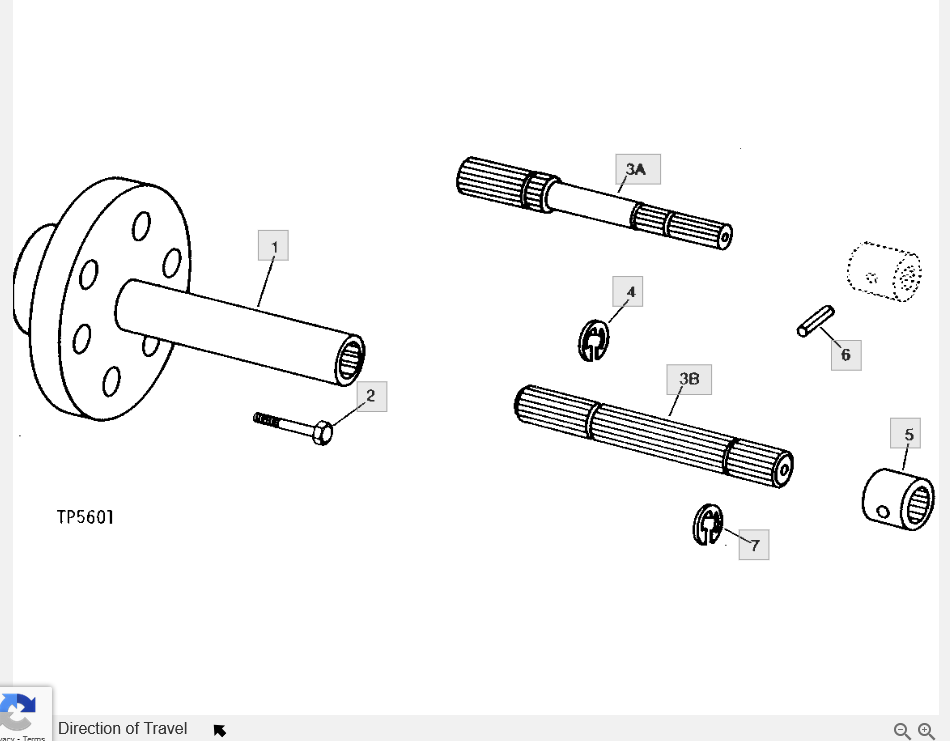

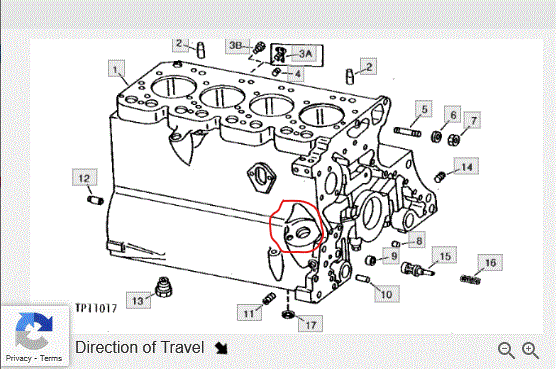

1) This picture would lead me to believe my dozer has had the "common sump" conversion done to it? Correct? Does that mean I can just take my 12 gallons of hydraulic/transmission fluid and pour it into the transmission dipstick/filler hole? Or do I have to "fill" it in other areas? I have only drained the final drives (plug on each side) and the main transmission bolt

2) Final Drive oil change. mg2361 lined me out already, but I just want to make sure I get it. The same fluid goes into the final drives as the steering compartments and the transmission itself (Hygard J20A/C spec)? I have like 20 gallons of the same fluid o_O

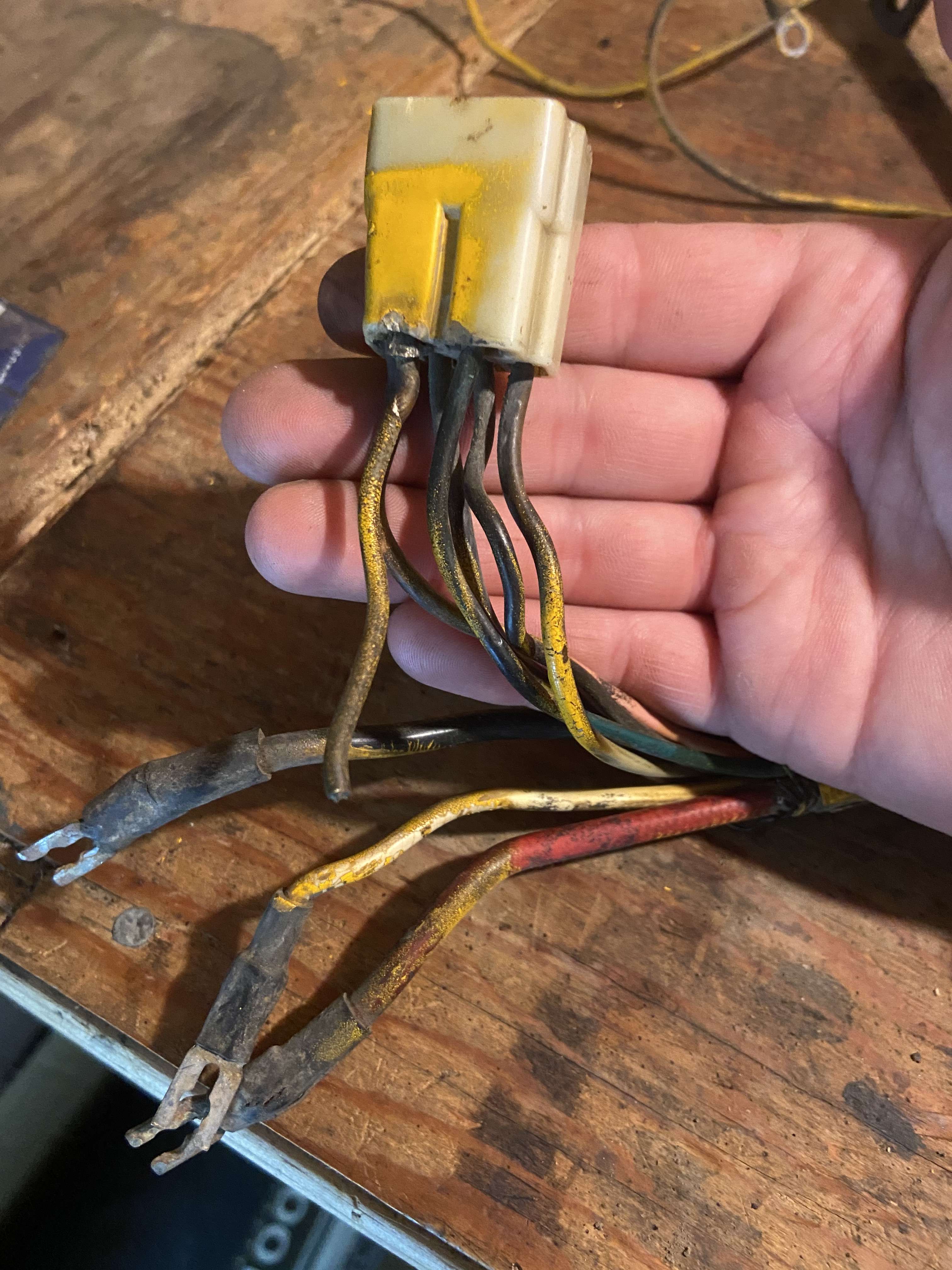

3) The wiring has been, well....lots of work. I finally found my serial # and have pretty much dialed in the entire cluster, and everything down stream of the "main wiring plug connector". The technical manual has been really helpful in terms of understanding what is going on. Here is my question...someone cut the wire on the "engine wiring harness" that goes to the injection pump. I was just going to splice the wire and call it good but the thing is the wire terminal in the plastic connector is loose. HOW DO I REMOVE THE WIRE FROM THE PLASTIC CONNECTOR BODY? Most harnesses you just push a flat head screw driver into the connector and the wire terminal will "pop" loose...this isn't happening and I don't want to break the plastic connector body. A whole new harness is like 300 bucks

4) Gauges. Where the hell do I get new gauges? JD wants like 500 bucks for a new oil pressure gauge and another 500 for a tach!!! I found a used tach, water temp gauge, push button start but that is it (all ordered and on the way). I still need the trans temp, oil pressure, and alternator gauge.

Thanks in advance everyone. Def. more questions to follow, specifically on my alternator (what do I have, what do I need) and more wiring.