Post support questions about your JD350 and newer crawler here

-

Tigerhaze

- 350 crawler

- Posts: 2278

- Joined: Thu Jul 06, 2006 12:13 pm

- Location: West-Central MO

Post

by Tigerhaze » Tue Oct 16, 2007 9:47 am

First to help you with your pics (they are not showing up) you need to have the link for your photos between the following:

. A few of them started with the forward slash, which is part of why they are not showing up. Also you have a double [img] on the end of the third photo link.

I directly pasted the links into my browser and took a look at the photos.

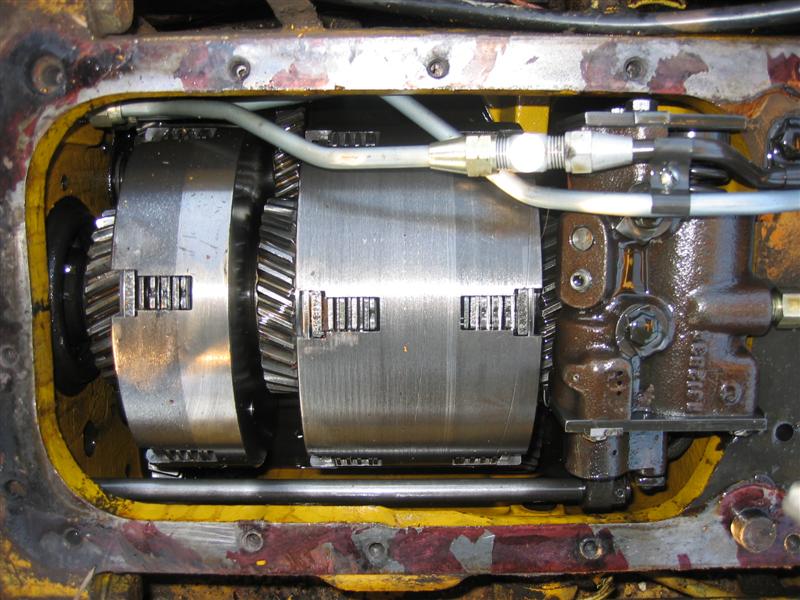

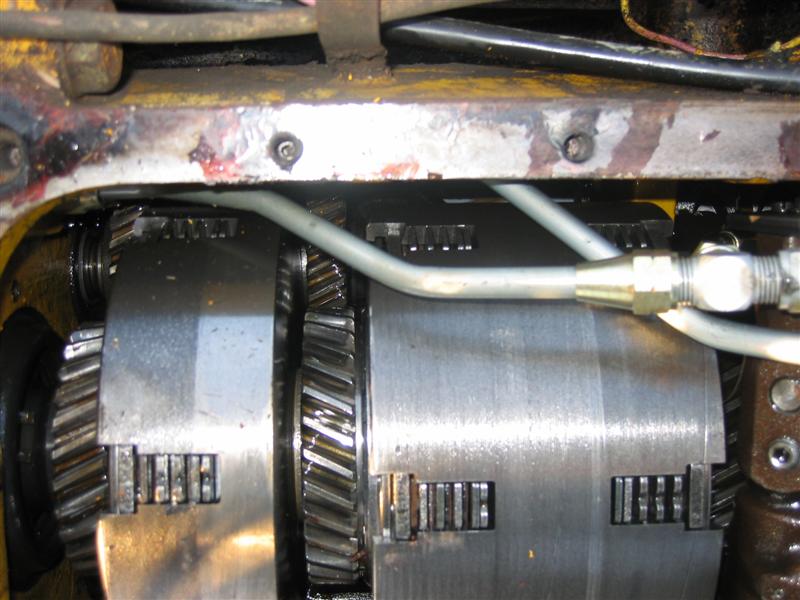

As for your track adjuster in the second photo, the shaft seems to be completely pitted and rusted. Even if you can get the adjuster to move through greasing, I would think the rusted shaft would damage the grease seals.

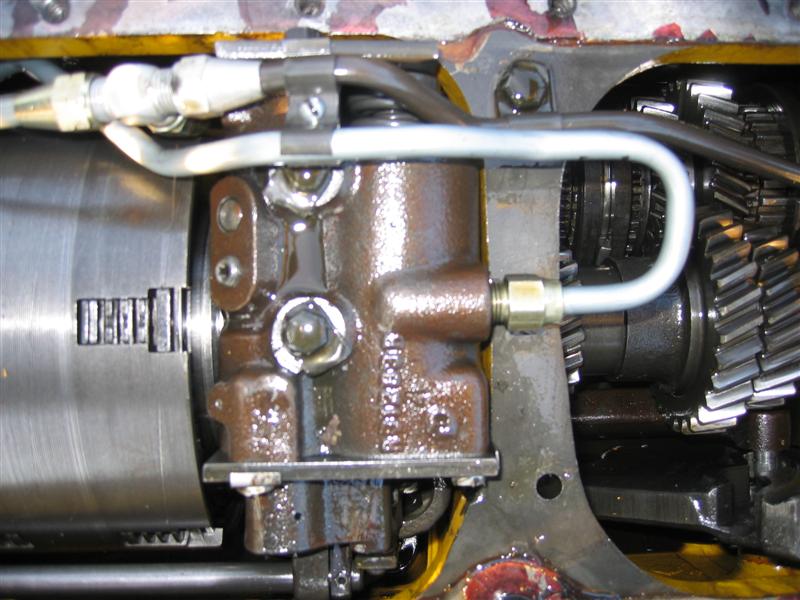

On the third photo, I am not seeing the broken part you mention. It does look like the adjuster rail on the track frame may be bent, which would keep you from completely retracting the adjuster if you needed to remove the track.

Just my two cents.

(1) JD Straight 450 crawler dozer with manual outside blade; (2) JD 2010 diesel crawler loaders; (1) JD 2010 diesel dozer with hydraulic 6-way blade; (2) Model 50 backhoe attachments, misc. other construction equipment

-

wwattson

- 1010 crawler

- Posts: 499

- Joined: Mon Aug 07, 2006 9:12 pm

- Location: West Bend, WI

Post

by wwattson » Tue Oct 16, 2007 11:57 am

Let me help with the pictures.

You need to use the Direct Link and not the Shared URL feature on PhotoBucket

Bill Wattson

-

CatD8RII

- 1010 crawler

- Posts: 324

- Joined: Mon Jan 16, 2006 9:26 am

- Location: PA

Post

by CatD8RII » Sat Nov 03, 2007 6:12 pm

the piece in the 3rd picture is a wear strip for the track frame. however it doesnt belong on the top it actually goes on the bottom side of that channel. The idler yoke has bolt on wear strips (pieces of 4140) that are supposed to ride against these under the weight of the crawler. These are adjustable via shims but the tracks gotta be off to do it.

-

jgbanshee

- 420 crawler

- Posts: 39

- Joined: Sat Sep 09, 2006 5:01 pm

Post

by jgbanshee » Tue Nov 06, 2007 7:30 pm

The brake pedal on my 450 was stuck down on my 450 for a while. Could the brakes cause the machine not to go in reverse?

-

OneWelder

- 420 crawler

- Posts: 47

- Joined: Wed Sep 19, 2007 5:21 pm

- Location: Derry, New Hampshire

Post

by OneWelder » Tue Nov 06, 2007 8:46 pm

Maybe i am thinking of a different model but the way i remember these is

A. track adjuster seals mount on the end of rusty rod and slide back and forth in barrel mounted on idler bracket

B The wear strip is positioned in the correct place. there should be larger one on top smaller one underneath. new wear strips are not a lot of money from Deere.

Suspect lack of preheat, or poorly adjusted idler pounding on wear strip caused it to start peeling.

-

CatD8RII

- 1010 crawler

- Posts: 324

- Joined: Mon Jan 16, 2006 9:26 am

- Location: PA

Post

by CatD8RII » Wed Nov 07, 2007 5:20 pm

I know the 350s only put strips on the bottom, maybe the 450s are different (the parts book only calls for a qty of 4 strips?) It would make sense as that area on the track frame would wear some over time. However even the new JD 650Hs and Cat D5Gs only put strips on the bottom, but they dont make stuff like they used to. The rusted part is called a piston or rod , it needs to look like a hydraclic cylinder rod (nice and chrome) where it goes into the barrell of the cylinder. In the cylinder there should be an o-ring with a back-up ring and then a wiper seal on the outside.

-

OneWelder

- 420 crawler

- Posts: 47

- Joined: Wed Sep 19, 2007 5:21 pm

- Location: Derry, New Hampshire

Post

by OneWelder » Wed Nov 07, 2007 9:46 pm

Try the parts cat. 2 on top- 2 under = 4 wear strips per track frame

The rusty rod-(which is the piston)is pushed out of the barrel (cylinder)by the grease pushing on seal & end of rod. The rod was only chromed for the first few inches, if you have grease at chrome the track adj. has failed- seal is leaking. There is Also a seal at the end of the barrel which rides on the chrome- this seal is to keep dirt out of trk.adj. so you do not cut adj. seals if you need to loosen the tracks & to keep barrel clean for future adj.[/img]

-

CatD8RII

- 1010 crawler

- Posts: 324

- Joined: Mon Jan 16, 2006 9:26 am

- Location: PA

Post

by CatD8RII » Thu Nov 08, 2007 9:26 am

The straight 450 parts book doesnt say if its 4 per frame or machine, but if you look up a 450C it clearly shows 4 strips per frame one on top and one on the bottom. They probably didnt use it on the 350s to keep costs down, and its probably why they still dont do it on the newer machines

-

OneWelder

- 420 crawler

- Posts: 47

- Joined: Wed Sep 19, 2007 5:21 pm

- Location: Derry, New Hampshire

Post

by OneWelder » Thu Nov 08, 2007 10:01 am

I used straight 450 parts cat. - but admit that is confusing the way they list it - study the picture a little closer

This was a popular machine around here when they were younger and I have changed a lot of bottoms on them, which always included replacing wear bars.

-

CatD8RII

- 1010 crawler

- Posts: 324

- Joined: Mon Jan 16, 2006 9:26 am

- Location: PA

Post

by CatD8RII » Thu Nov 08, 2007 12:20 pm

I shouldnt have assumed off of the qty like i did, i just figured that my little 350C only has them on the bottom and we run alot of 650Hs at work which only have them on the bottom as well .In any event its a better desing on having them on the top too. Once the machines with only 1 wear strip wear out on the top side all you can do is weld the grooved part in the track frame up and grind it smooth. We do alot of that at work as Cat D5Gs horrible for this, their idlers dont even have bolt on wear strips on them. Then they start jumping around until they blow out the track adjuster. The 650s arent as bad, needless to say im not a big Cat fan when it comes to small machines.

Who is online

Users browsing this forum: No registered users and 169 guests