pernsdorff wrote: Isolator is an odd looking setup. The springs seem quite loose. That plate can be moved about a fair amount -- almost an inch of twist by hand.

Does this play sound exsessive? I assume the fix for this is new springs?

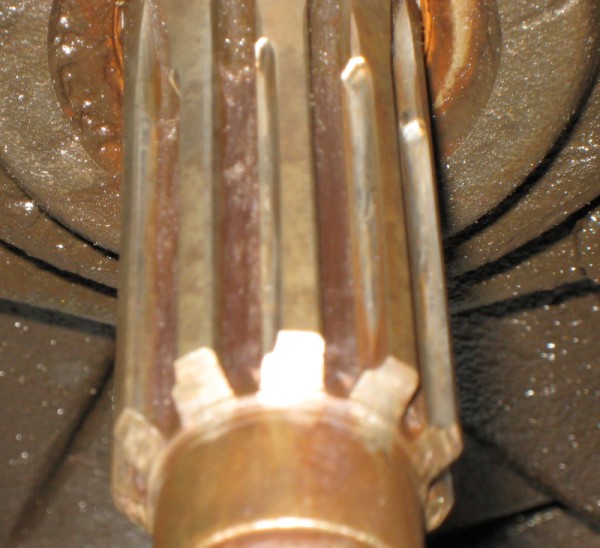

They are rattle-traps even when all the parts are new. Judging by your spline wear - I'm going to assume your isolator parts are worn. Look closely. The anchor posts that the springs attach too - on the flywheel and also on the center-plate are usually worn. The angles clips that bolt to the flywheel are usually worn. The stop-pins that are driven into the flywheel are usually hammered, bent, and/or broken. The center-plate usually has the brake-lining material ripped off it (it's supposed to have a facing on it where it contacts the flywheel. And, how are the splines in it where the input shaft goes into it? And, then there's the springs. They are just about always out of spec - but check your Deere tech manual - it will give you proper specs as to length. Look at the end-hooks for wear.

Keep in mind that when we were fixing them - these crawlers were being used daily - all day, every day. They weren't part-time collector's items.

I've probably fixed hundreds of isolators -and usually all parts get replaced when durability is an issue. You also have to use a lot of Loctite when assembling or it will fall apart. All that needs to happen is one of the angled-clips to twist a little and it will contact the clutch/transmission housing and all will fall apart.

The best way to go - IF all the parts are highly worn - and you really plan on using the crawler hard - is to upgrade to the newer setup. It doesn't cost much more and will never come apart.

If it's just a part-time user - then just patch it up best as you can. Maybe new springs if your's are stretched and lots of Loctite. If the front shaft if fairly tight - pull the front pump and check it for wear, install a new front seal - and leave the rest alone and take your chances.

In regard to the reverser - the #1 failure point is the center-bearing inside the reverser. It was too small in the early machines - but got upgraded to a larger bearing with the "B" series. So, hopefully, you've got the bigger one. When it gets worn, the front input shaft will show excessive end-play. That because they are all in one line - the front input shaft bearing, then the center bearing between the input and output shaft, and the the bearing at the end of the output shaft. Since they are all in one line, and if any one of them wears - the entire assembly gets loose. Since the centerbearing is smaller then the rest - it is the first to wear. It only turns when the reverser is used in reverse. That is why reverse is weaker than forward.