Newbie Attaching backhoe to 450C crawler

-

Donnie_Ray

- 40C crawler

- Posts: 13

- Joined: Fri May 07, 2010 12:43 pm

- Location: New Brunswick Canada

- Contact:

Newbie Attaching backhoe to 450C crawler

Hi everyone,

I just recently purchased a 1975 450C crawler and I'm a total newbie around any kind of mechanical equipment. I probably have no business having one of these machines but I thought it would be great fun working on my wood lot roads and possibly preparing a site for a house.

I got a 930 backhoe along with the crawler and I am trying to figure out how to connect the hydraulics. I bought the service manual but that doesn't seem to help at all. It mentions a selector valve for diverting the hydraulic flow from the front of the machine to the rear but I can not find any such valve. Did these machines not come with a selector valve or if they did where would I find it? Any information/advice would be most appreciated.

Thanks for your help,

Don

I just recently purchased a 1975 450C crawler and I'm a total newbie around any kind of mechanical equipment. I probably have no business having one of these machines but I thought it would be great fun working on my wood lot roads and possibly preparing a site for a house.

I got a 930 backhoe along with the crawler and I am trying to figure out how to connect the hydraulics. I bought the service manual but that doesn't seem to help at all. It mentions a selector valve for diverting the hydraulic flow from the front of the machine to the rear but I can not find any such valve. Did these machines not come with a selector valve or if they did where would I find it? Any information/advice would be most appreciated.

Thanks for your help,

Don

-

JWB Contracting

- 2010 crawler

- Posts: 598

- Joined: Thu Aug 27, 2009 10:08 pm

- Location: Edmonton, Alberta

450 dozer backhoe attachment

The book is correct in that you need a diverter valve to power the backhoe. It diverts the hydraulic flow from the dozer functions to the backhoe. If your crawler has one it would be under the right hand lid beside the operators seat. If you don't see one, then you have a couple options:

1. Buy the diverter valve and install. I personally do not like these as you have to switch the valve to operate the backhoe vs. the dozer. Tough to puch the crawler ahead with the hoe when you need to pick up the dozer (i put the dozer down to keep the machine from rolling when digging)

2. Plumb a tee into the high pressure line coming from the pump, add a seperate relief value and add a low pressure return line. We did this on our 450C widepad dozer and it works great. We mounted the extra relief valve under the seat so there is not much room under there now. Have had the cat for 5+ years and would do the same system again if i rigged up another cat. You will need someone knowledgable about deere hydraulics to design the system for you. Mostly likely costs less than the factory set up and performs better.

1. Buy the diverter valve and install. I personally do not like these as you have to switch the valve to operate the backhoe vs. the dozer. Tough to puch the crawler ahead with the hoe when you need to pick up the dozer (i put the dozer down to keep the machine from rolling when digging)

2. Plumb a tee into the high pressure line coming from the pump, add a seperate relief value and add a low pressure return line. We did this on our 450C widepad dozer and it works great. We mounted the extra relief valve under the seat so there is not much room under there now. Have had the cat for 5+ years and would do the same system again if i rigged up another cat. You will need someone knowledgable about deere hydraulics to design the system for you. Mostly likely costs less than the factory set up and performs better.

Jason Benesch

John Deere 420, 430, 440 & 350C With 3 Point Hitch

John Deere 400G With Winch

John Deere 2010 Crawler Dozer

John Deere 420, 430, 435 & 440 Wheel Tractors

John Deere 420, 430, 440 & 350C With 3 Point Hitch

John Deere 400G With Winch

John Deere 2010 Crawler Dozer

John Deere 420, 430, 435 & 440 Wheel Tractors

-

Donnie_Ray

- 40C crawler

- Posts: 13

- Joined: Fri May 07, 2010 12:43 pm

- Location: New Brunswick Canada

- Contact:

450 backhoe attachment

Thanks Jason. I plan to go with your second suggestion. It costs less and performs better. Can't beat that combination.

Don

Don

-

Donnie_Ray

- 40C crawler

- Posts: 13

- Joined: Fri May 07, 2010 12:43 pm

- Location: New Brunswick Canada

- Contact:

Hi Ken,

My 450 is a loader and yes it did come with the hoe mount and I have the hoe now attached to the crawler, just trying to figure out the best way to plumb it.

Assuming that my hoe has an open center valve body (please excuse my ignorance but how is this determined?), would I not want to have more of the oil flowing to the backhoe than to the front of the machine? Would it make sense to put in a flow divider to control the percentage of oil that goes to the front and back?

My 450 is a loader and yes it did come with the hoe mount and I have the hoe now attached to the crawler, just trying to figure out the best way to plumb it.

Assuming that my hoe has an open center valve body (please excuse my ignorance but how is this determined?), would I not want to have more of the oil flowing to the backhoe than to the front of the machine? Would it make sense to put in a flow divider to control the percentage of oil that goes to the front and back?

If you have 2 levers the outside one is the auxilary. The inside lever actuates the first two valve in the stack and the second lever operates the third auxilary valve. The hoe operates off the power beyond section of this valve. The diverter was only used if you were operating front mounted equipment as well like a 4 in 1 bucket and a ripper. I think I have diagram of this system I'll try and scan it this afternoon. I'll elaborate as soon as I get a chance to look for it.

Matt

Matt

You will need to but a tee in the return inlet of the tank. This will be your return from the hoe. The supply comes from the power beyond sleeve of the aux valve. The typical inlet/outlet port would be plugged.

Does anyone have a schematic of this aux valve? could you run front mounted equipment and a hoe off this valve or is it "one or the other". I don't have a diagram in any of my books.

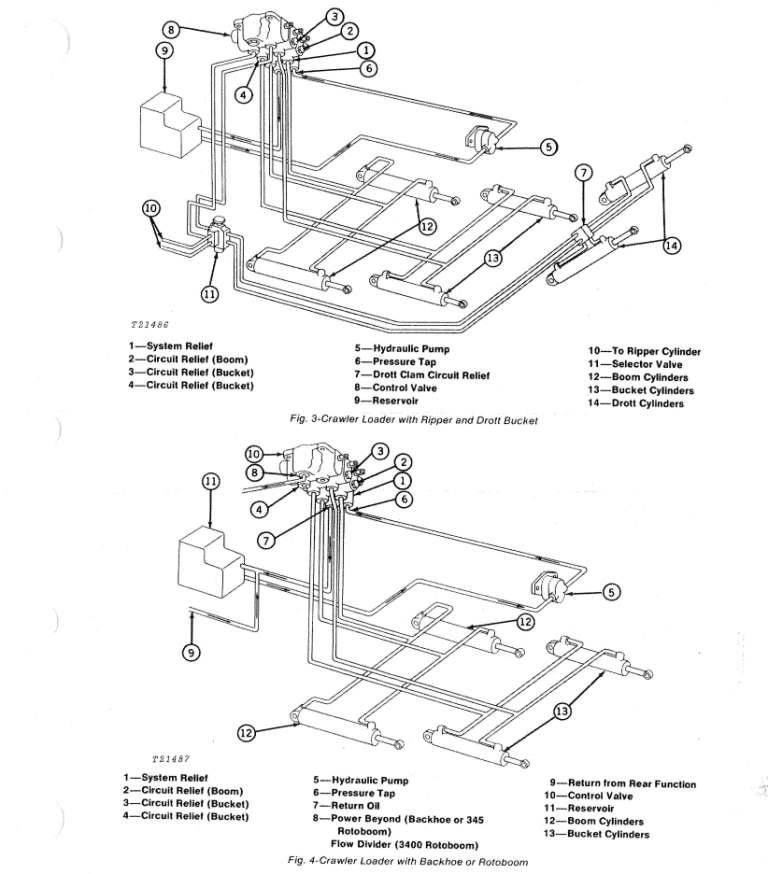

As a side note I believe the picture i posted is from a B model I'm not sure if there is any difference, but it should be similar. You can see in the top picture when the diverter valve is needed.

Hope this helps

Matt

-

Donnie_Ray

- 40C crawler

- Posts: 13

- Joined: Fri May 07, 2010 12:43 pm

- Location: New Brunswick Canada

- Contact:

Thanks for all the information Ken.

My machine has never had a backhoe on it. There are no lines coming off of the crawler like in your picture, but there are lines like it coming off of the backhoe. The person I bought the crawler and backhoe from was given the backhoe and mounting bracket but unfortunatley his friend never got around to giving him the hydraulic lines.

I have the crawler and backhoe at a friend's welding shop and his men were able to attach the backhoe without the hydraulics being connected. They also had to modify the mounting bracket since the bolt holes didn't line up. The mounting bracket came off of a 450C but I think it was a few years newer.

My welder friend has some hydraulic experience but wasn't sure exactly how to plumb for the backhoe, which led me to making this post.

Below is a picture of my machine with the backhoe on in Jimmy's welding shop.

[/img]

[/img]

My machine has never had a backhoe on it. There are no lines coming off of the crawler like in your picture, but there are lines like it coming off of the backhoe. The person I bought the crawler and backhoe from was given the backhoe and mounting bracket but unfortunatley his friend never got around to giving him the hydraulic lines.

I have the crawler and backhoe at a friend's welding shop and his men were able to attach the backhoe without the hydraulics being connected. They also had to modify the mounting bracket since the bolt holes didn't line up. The mounting bracket came off of a 450C but I think it was a few years newer.

My welder friend has some hydraulic experience but wasn't sure exactly how to plumb for the backhoe, which led me to making this post.

Below is a picture of my machine with the backhoe on in Jimmy's welding shop.

[/img]

[/img]-

Donnie_Ray

- 40C crawler

- Posts: 13

- Joined: Fri May 07, 2010 12:43 pm

- Location: New Brunswick Canada

- Contact:

Ken, if not too much trouble, a couple of pictures would be great. Yes, my hoe is a 9300 model and I do believe the loader control valve does have "power beyond" capability, at least that is what my welder friend has concluded.

I believe I now have all the information needed to have the hoe plumbed correctly. I'm really looking forward to getting on it and digging a big hole, just because I can Unfortunately it will have to wait a few weeks since I'm heading to Arizona and California in a few days to do some hiking and photography.

Unfortunately it will have to wait a few weeks since I'm heading to Arizona and California in a few days to do some hiking and photography.

Thanks for all of your help!!

I believe I now have all the information needed to have the hoe plumbed correctly. I'm really looking forward to getting on it and digging a big hole, just because I can

Thanks for all of your help!!

This was really helpful for someone like me that is still learning hydraulic systems- thank you!KenP wrote:OK, I pulled the books on my backhoe valve body.

To tell if the hoe is open or closed center, look at the hydraulic supply and return lines positions where they screw into the hoe's valve block.

If they are on opposite ends of the valve stack, its open center.

If they are on the same end, one above the other, its closed center.

(1) JD Straight 450 crawler dozer with manual outside blade; (2) JD 2010 diesel crawler loaders; (1) JD 2010 diesel dozer with hydraulic 6-way blade; (2) Model 50 backhoe attachments, misc. other construction equipment

Open and closed center refers to the fact that if the spool is in the normal position (could be center, right, etc depending on how many position it is) will fluid pass through the valve to the return or not.

Open center will allow fluid to pass back to tank therefore the fluid is constantly flowing at a relatively low pressure. It is not until a valve is actuated and the fluid has to do "work" and the pump will generate operating pressure and actuate the cylinder or what ever it is attached to. This system is usually used with a continuous flow type pump (most industrial equipment). This system allows the fluid to flow back to the tank through the valve and not through the relief. This means it will not generate anywhere near as much heat.

Closed center is always at max pressure, but is usually used with a variable displacement pump. The pump will "throttle back" it's flow when it is not needed. However there still needs to be flow through the pump. Therefor the fluid must return through the relief valve. This still generates heat, but since it is at a much lower volume it does not generate as much.

All hydraulic systems have a relief valve as a safety measure. Otherwise if the system were to deadhead it would stall the pump.

Power beyond is the key in this situation. It allows full pump flow to power another system (ie valve block for a backhoe) without it you would lose flow if another system upstream (ie the loader) were actuated.

Although people do it all the time you shouldn't plumb another valve into the return of an existing valve.

I hope this was helpful for someone. If you have any specific questions let me know. There is a lot to a properly designed hydraulic system and a lot to lose if it's not done right.

Matt

Open center will allow fluid to pass back to tank therefore the fluid is constantly flowing at a relatively low pressure. It is not until a valve is actuated and the fluid has to do "work" and the pump will generate operating pressure and actuate the cylinder or what ever it is attached to. This system is usually used with a continuous flow type pump (most industrial equipment). This system allows the fluid to flow back to the tank through the valve and not through the relief. This means it will not generate anywhere near as much heat.

Closed center is always at max pressure, but is usually used with a variable displacement pump. The pump will "throttle back" it's flow when it is not needed. However there still needs to be flow through the pump. Therefor the fluid must return through the relief valve. This still generates heat, but since it is at a much lower volume it does not generate as much.

All hydraulic systems have a relief valve as a safety measure. Otherwise if the system were to deadhead it would stall the pump.

Power beyond is the key in this situation. It allows full pump flow to power another system (ie valve block for a backhoe) without it you would lose flow if another system upstream (ie the loader) were actuated.

Although people do it all the time you shouldn't plumb another valve into the return of an existing valve.

I hope this was helpful for someone. If you have any specific questions let me know. There is a lot to a properly designed hydraulic system and a lot to lose if it's not done right.

Matt

Who is online

Users browsing this forum: No registered users and 9 guests