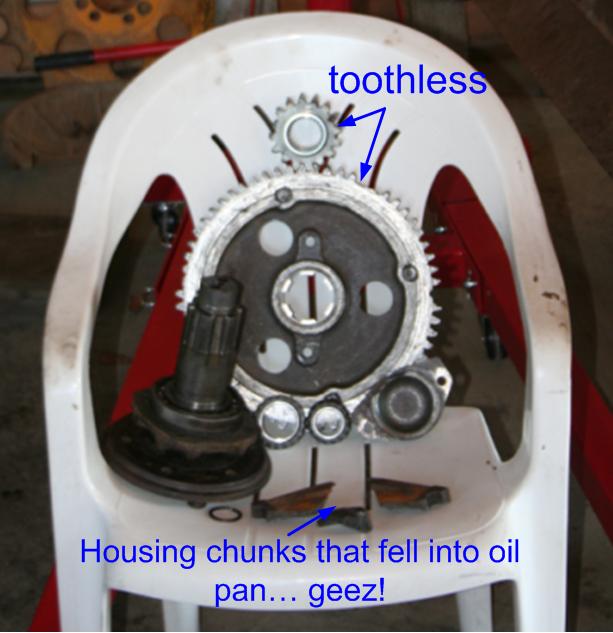

I'm in this spot because I hit a rock, busted chunks of the housing into the oil pan, then catastrophe ensued. For those of you who like gore... see my busted parts:

I replaced everything in the final drive housing (bull gear, pinion gear, bearings, seals, and the housing too.

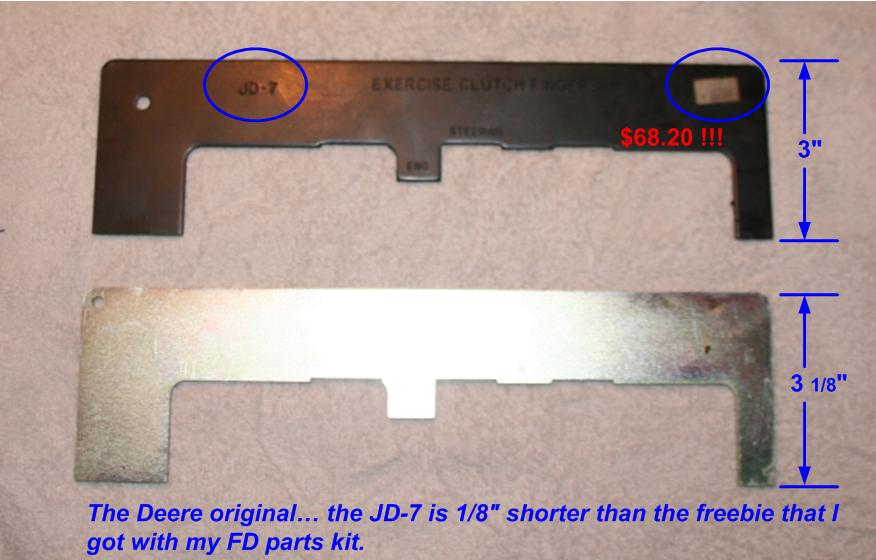

With the parts, I got a freebie clutch guage. Look's like it's been plasma cut from plate stainles, using an original Deere guage as a template.

Now, my brother-in-law (he's got a 40c) pops over with his Deere original guage, stamped 'JD-7', with markings (and a $70 price tag!) and looking all official and stuff.

The two gauges were different. The JD-7 guage will set the tangs about 1/8" farther from the the throw-out bearing than the freebie guage.

See the guages:

I decided to go with the Deere original guage. I tweeked the clutch plate adjustment nuts accordingly, then reassembled the whole thing, track included.

Just so you don't think I'm a complete dufus, before I put the track on, I started her up and saw that stuff moved like it should.. (but I did not test the brake).

You know the rest of this story.... backed the crawler out of the barn, and started out for my ride of pride.

But she decided to switch parties and become a Republican crawler... only steers to the right!

The throw-out isn't throwing out. I don't think it's even contacting those clutch plate tangs.

The silver lining is that the brake works, because when I give the stick a serious yank, I stall the engine... both steering clutch and brake simultaneously engaged. (This is not good)

My theory is that I should of used the guage I got with the parts.

Every dang time I listen to my brother-in-law........

Ran out of time on this for today, so I'll have at it later in the week...

I'm sure not excited about banging out that master link pin on the track again.

Arm's still sore from swinging the 20oz peen to bang it in.

Dear reader... please feedback whether you think I'm on the right track (no pun intended) here.

Emmett[/img]