The dozer has new clutches and brake bands. After getting everything back together the dozer would not move. This is the condition it was when the owner purchased it 3 years ago. So now it has new clutches, brakes and one new bearing in the left final drive.

The following details the pressure testing we did.

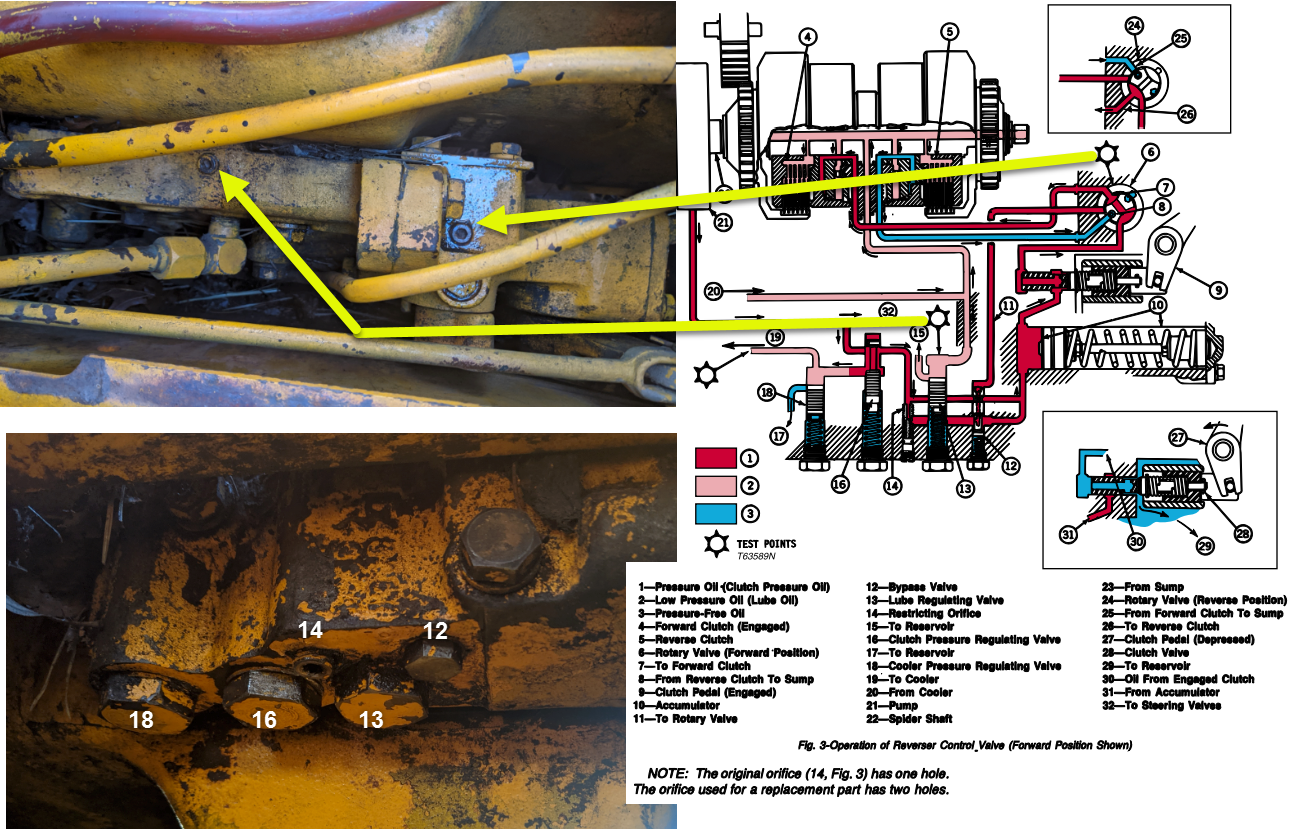

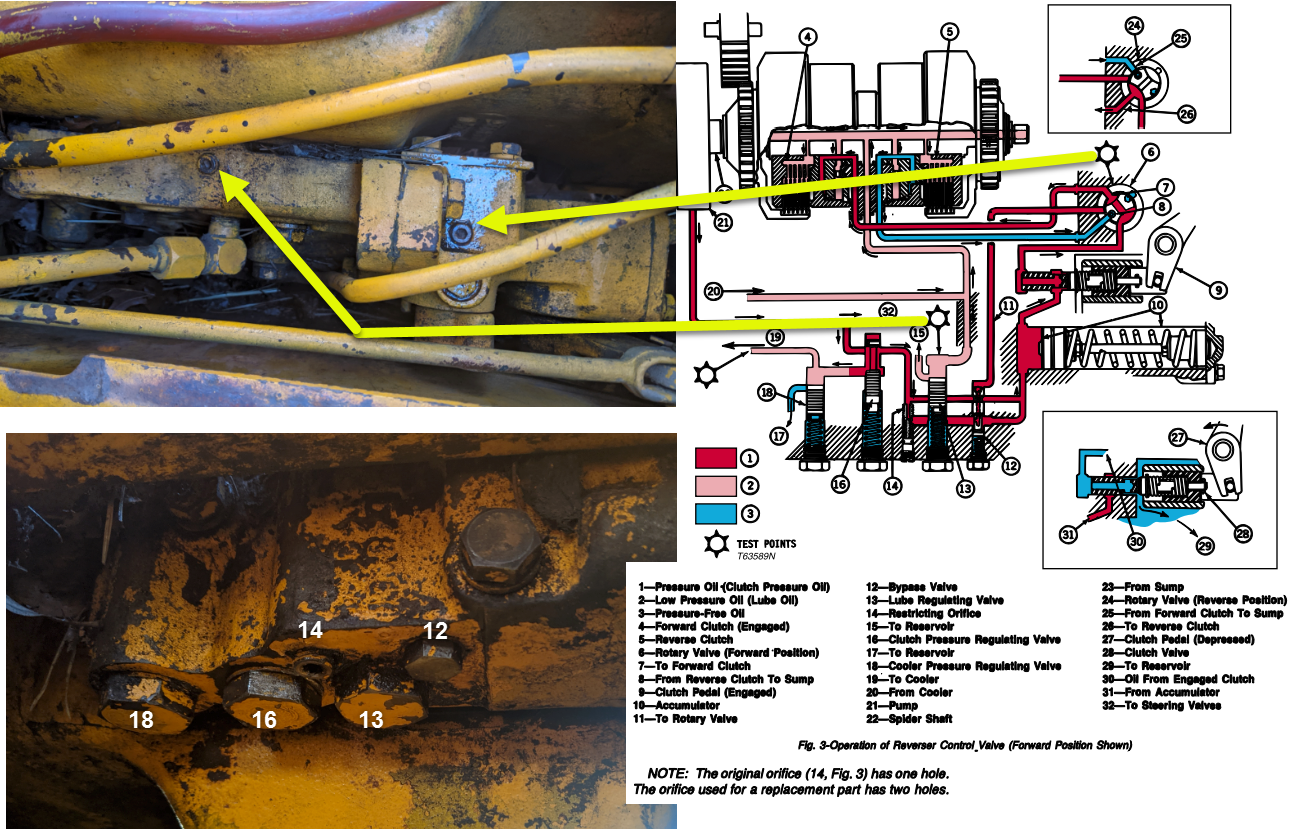

Below is a diagram of the Reverser Control Valve with pictures of the one in the dozer I am working on.

This shows the two (2) test points that are 1/8 NPT plugs and the regulating valve plug locations on the bottom of the valve body:

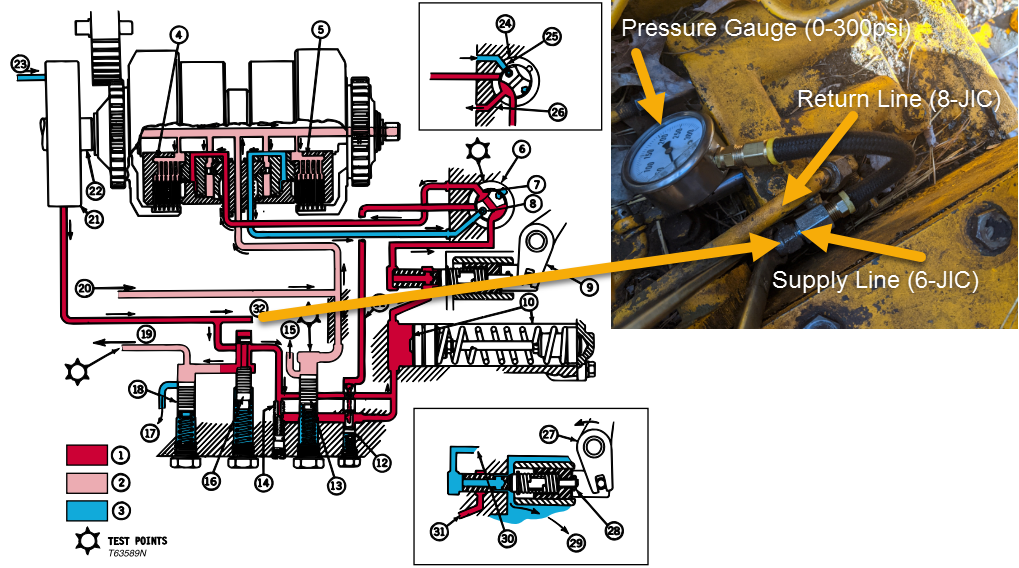

I used the same 300PSI gauge for all testing. The gauge has a 6" flexible hose connection with 1/4" Male NPT.

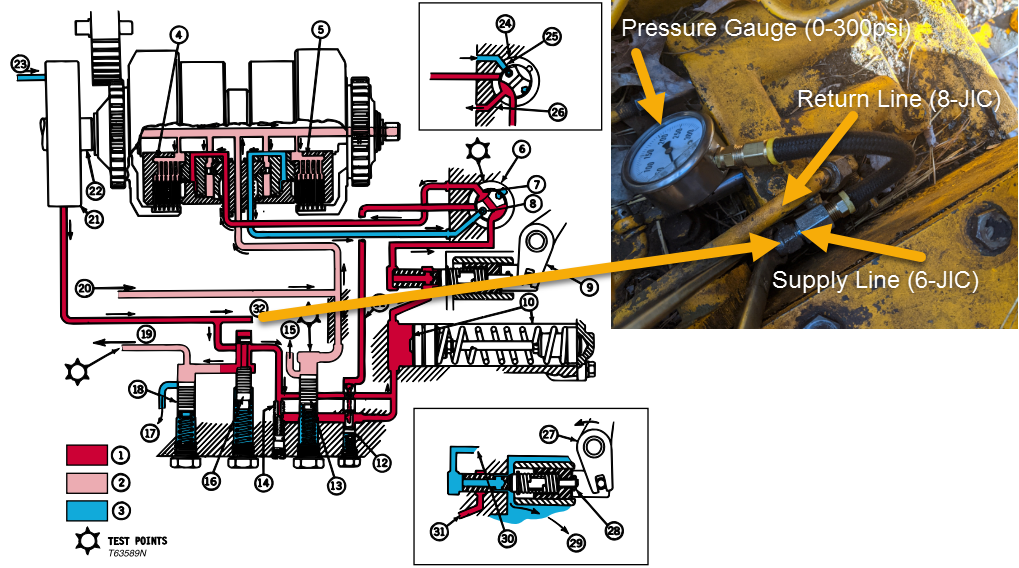

I used two different adapters to do the pressure tests.

One adapter is a Male 1/8" NPT to Female 1/4" NPT. This adapter was used on the two 1/8" NPT plug test points on the Control Valve. I needed to add a 4" 1/8" pipe to the rear test port (Rotary Valve area) because the 1/8" adapter wouldn't fit screwed directly into the valve body.

The other adapter was a Male 6-JIC to Female 1/4" NPT that was used to connect to the pressure line that feeds the Clutch Valve Body under the seat.

The gauge was plugged into the Lube Regulating Valve test point. The dozer was started (it was already warmed up to make sure all fluids were at temp). The gauge read 17-20psi, regardless of reverser lever position (neutral, forward, reverse) or the clutch position. This was at the lower end of the pressure limits in the manual (17-32psi)

The gauge was then plugged into the test port above the rotary valve using the 4" 1/8" pipe extender and adapter. The dozer was started again. Pressure read 25psi regardless of reverser lever position (neutral, forward, reverse) or the clutch position. This was supposed to be 150psi for the 350C model.

The next step was to determine if the issue was in the Reverser or maybe the Clutch Valve Housing was leaking and allowing pressure to return to the sump.

So we disconnected the hydraulic pressure and return lines to the Clutch Valve Housing. This required the use of two modified open end wrenches (ie grinding the sides down enough to be able to rotate the fittings.) The pressure gauge was connected to the pressure line (#32 in the diagrams) using the 6-JIC adapter.

The tractor was started and the gauge read 25psi. This seemed to indicate the issue was in the Reverser and not the Clutch housing.

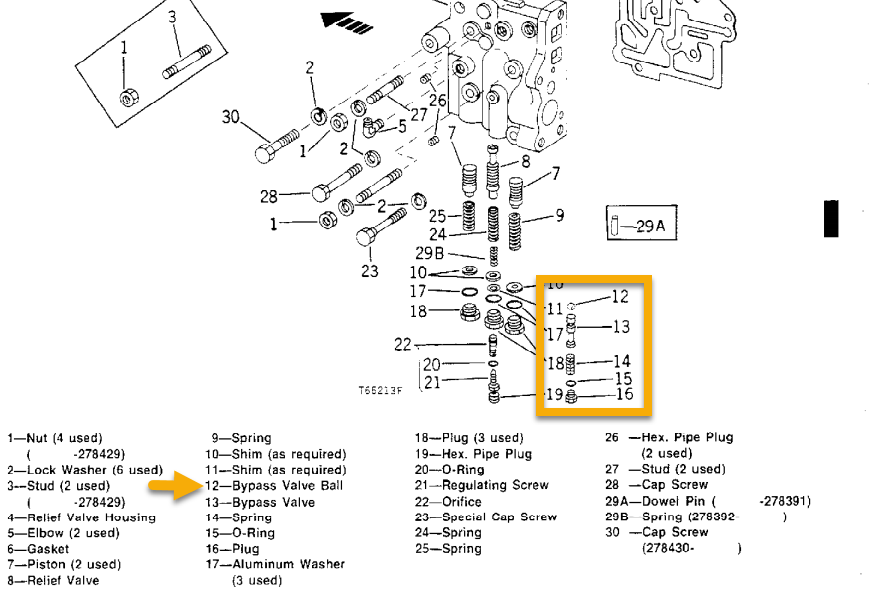

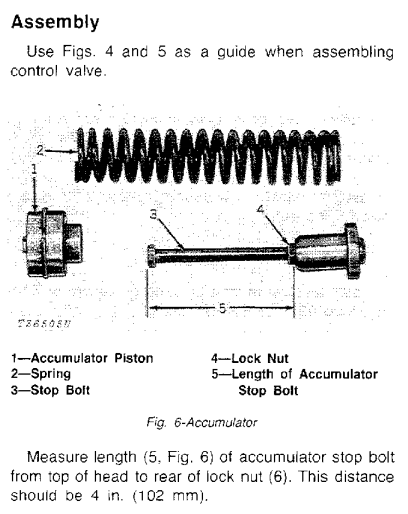

On a previous trip to work on this dozer we had the Clutch Regulating plug pulled out with the penny shim and spring removed. The spring went back in very hard. With this in mind we thought maybe the valve was stuck in the bore. We pulled the plug (1 1/8" socket required) and removed the penny and spring. I could feel the end of the control valve but could not get it to move up or wiggle or anything.

Luckily the owner had another valve body laying in some leaves. This "spare" unit was also from a 350C. We removed the Control Valve plug, found three washers as shims and a duel spring assembly. The valve was stuck in this unit, most likely due to sitting outside for a looong time. We sprayed it with a bunch of WD-40. Then, with a tap from a punch and hammer, we got the valve to break free. We were able to remove it and then re-insert easily. Pushing the valve all the way in we took a rough finger depth measurement to compare to the valve position in the dozer. The dozer valve was way low in the bore and stuck, thus allowing pressure to bypass.

I was able to get a 1/4" socket extension into the control valve hole and then pry it up against the valve. The valve broke free and moved up a lot. It moved up enough that putting the spring and shim back in was A LOT easier.

We started the dozer back up with the pressure gauge still connected to the pressure line (#32) at the clutch housing. The gauge read 200PSI when the reverser was in forward or reverse. This was a major change from the 25psi we had early. The pressure dropped to zero when the clutch was pressed, or when the reverser lever was put in neutral. It appears to have shown the issue was a stuck clutch pressure regulating control valve.

Below shows the connection of the pressure gauge at the clutch valve housing:

We connected the hydraulic lines back up to the Clutch Valve Housing, moved the pressure gauge back to the test port above the rotary valve and started the tractor. We were able to move the tractor in first gear, forward and backwards with the reverser. After adjusting the brakes we were able to turn the tractor in both directions and push some dirt. The dozer would stop pushing without bogging the motor or spinning the tracks. So we have some good progress but a lack of power. The gauge was only reading 50PSI. It would go to zero when the clutch was pushed in (If I recall correctly).

This creates a dilemma, I read 200 psi at the steering clutch valve housing prior to re-connecting the hydraulic lines. I didn't have a plug for the 6-JIC connector so I couldn't move the gauge to the rotary test port with the hydraulic line plugged to see if that test port had 200psi as well. So I don't know if the lack of power is because there's only 50 psi on the steering clutches, assuming that the pressure should be the same at the steering clutches and the rotary test port. This would seems to indicate the Clutch Regulating Pressure Valve is stuck again, maybe.

It got dark on us and so we had to stop work. We checked fluid level in the transmission before wrapping up. It was way low, not even up to the lower arrow. It was also kind of milky looking. I am assuming some water got into the system, or there was water in it from when it was disassembled. I was pretty sure we checked the oil levers first thing in the morning before we started working on it.

I'm assuming the fluid level was not allowing the new clutches to get "wet" enough to fully engage. We didn't move the tractor too much so I'm hoping we didn't damage the fibers on the new clutches. We will make sure the fluid level is full before the next test.

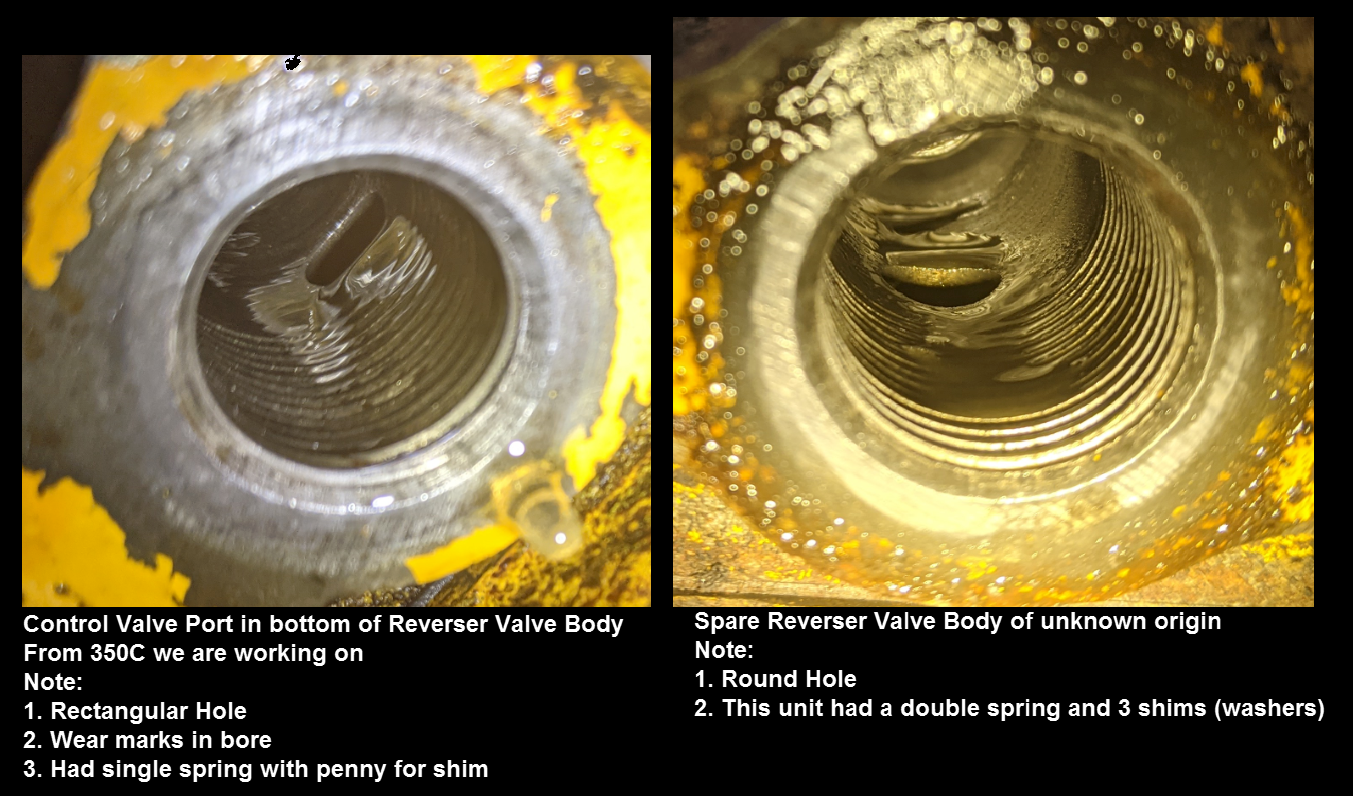

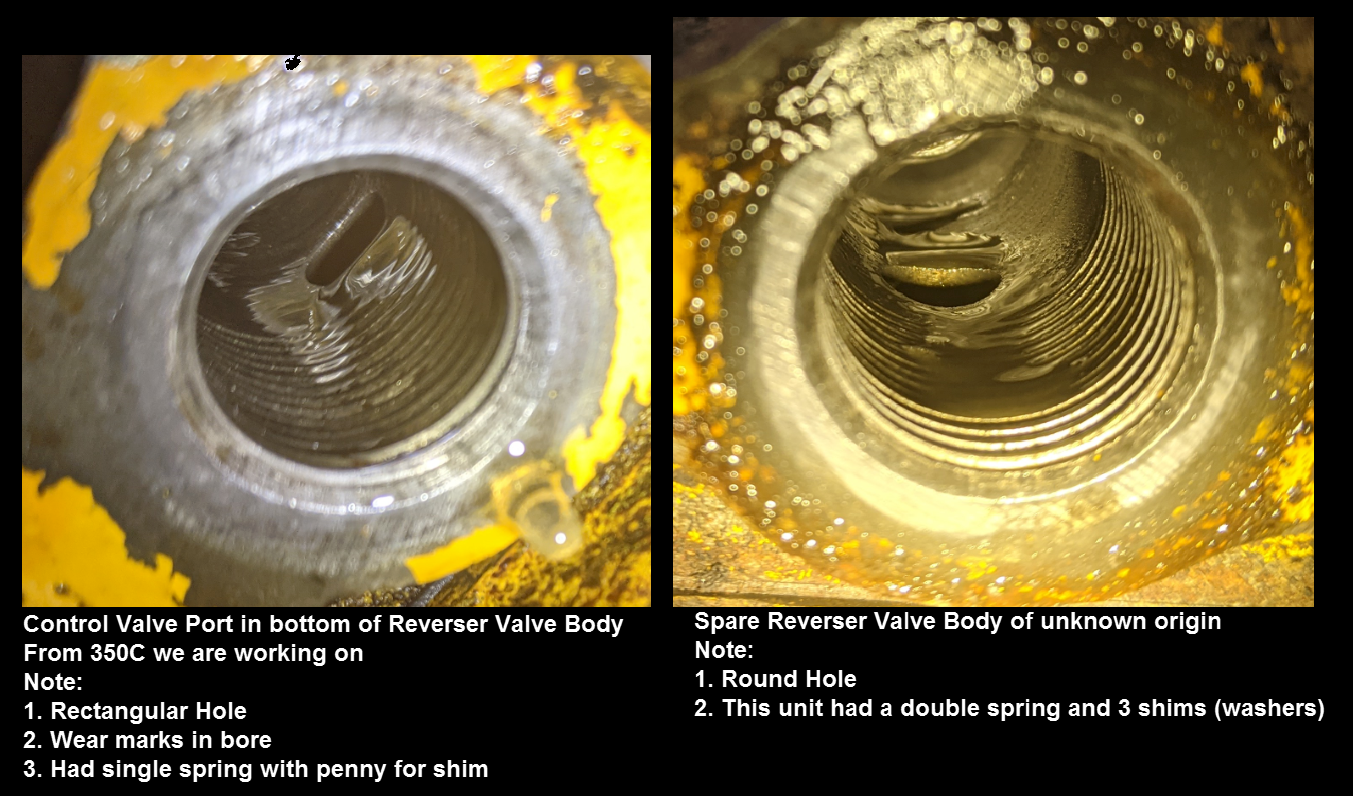

One observation of the Reverser Valve Body: we took a picture of the hole for the Clutch Pressure Regulating Valve bore, shown below:

The picture on the Left is from this dozer, serial number 301xxx.

The picture on the Right is from a 350C dozer of unknown serial number.

The hole in our dozer is oval/rectangular. The hole in the unknown valve body is round.

It also looks like there was some wear in the bore where the spring sits, This isn't in the area that the valve moves/seals so I don't think its an issue.

Now for some questions:

1. Should the pressure at the rotary valve test point be 150psi? Or is it lower as this is what feeds the reverser clutches?

2. Is 50 PSI enough to engage the reverser clutches (forward or reverse) and the steering clutches? The dozer did move pretty well, just wouldn't spin the tracks or bog the engine when pushing into a dirt pile.

3. Does the wear in the bore look like an issue?

4. Does it sound plausible that the low (extremely low) fluid in the transmission was causing the clutch slippage?

5. Can the Reverser Valve Body be removed without taking the reverser out of the dozer?

I'd really like to be able to "T" a pressure gauge into the hydraulic line going to the Clutch Valve Housing so I could monitor both the Rotary Valve pressure test point and the pressure to the Clutch Valve Housing. There's just not a lot of room to work in that area to do this.

I most likely won't get back to work on the dozer for a couple weeks so I'll be reading the manual and these forums trying to learn what I can about the reverser.

If you got this far thanks for reading

and thanks for any input or comments!