Gearmatic WinchDrum 8A Questions

- Stan Disbrow

- 350 crawler

- Posts: 2898

- Joined: Fri Jul 15, 2005 3:13 pm

- Location: Raleigh, NC

Hi,

You have to upload your photos elsewhere, like to photobucket. Then, copy the link into a post.

Here is a link to a thread about how to do it:

http://www.jdcrawlers.com/messageboard/ ... php?t=3690

Stan

You have to upload your photos elsewhere, like to photobucket. Then, copy the link into a post.

Here is a link to a thread about how to do it:

http://www.jdcrawlers.com/messageboard/ ... php?t=3690

Stan

There's No Such Thing As A Cheap Crawler!

Useta Have: '58 JD 420c 5-roller w/62 inside blade

Useta Have: '78 JD350C w/6310 outside blade

Useta Have: '68 JD350, '51 Terratrac GT-25

Have: 1950 M, 2005 x495, 2008 5103 (now known as 5045D)

Useta Have: '58 JD 420c 5-roller w/62 inside blade

Useta Have: '78 JD350C w/6310 outside blade

Useta Have: '68 JD350, '51 Terratrac GT-25

Have: 1950 M, 2005 x495, 2008 5103 (now known as 5045D)

- RacinJason

- 430 crawler

- Posts: 72

- Joined: Wed Aug 29, 2012 6:41 am

- Location: Spfld, MA/ Corinth, ME

Gearmatic 8A

I think someone posted some info on their homemade controller, using 2 brake master cylinders. My winch is beyond needing a controller, as it seems to be missing many parts. I have adapted a 2" receiver to mount on the towbar, so I could use my 8000# electric winch if I needed to. The winch is mounted on a Harbor Freight 2" Hitch Mount, which I normally use on a 3 Point hitch trailer mover attachment for my Yanmar.

JD 112, JD 420 C

Paul Buhler wrote:Notmeu is our new resident expert - he's really tearing his winches apart.

Tom: I'd like to see some pictures of your clutch spider and shaft and hear any thoughts you have on its removal. I've never removed mine, and I think it may be a "next" project so I can get better clutch adjustments. Thanks.

BTW, I sent you a PM earlier. Paul

Well Paul here is some photos for you. The clutch spider was a royal pain to remove from the drive shaft. It took lots of heat from a rosebud, there is 2 Jack bolts to help lift the spider off but I had to use a gear puller along with the Jack bolts and heat. It took a total of 4 days to remove it because the spider and shaft would get too hot and when everything expands production comes to a screeching hault.

A pre-disassembly photo.

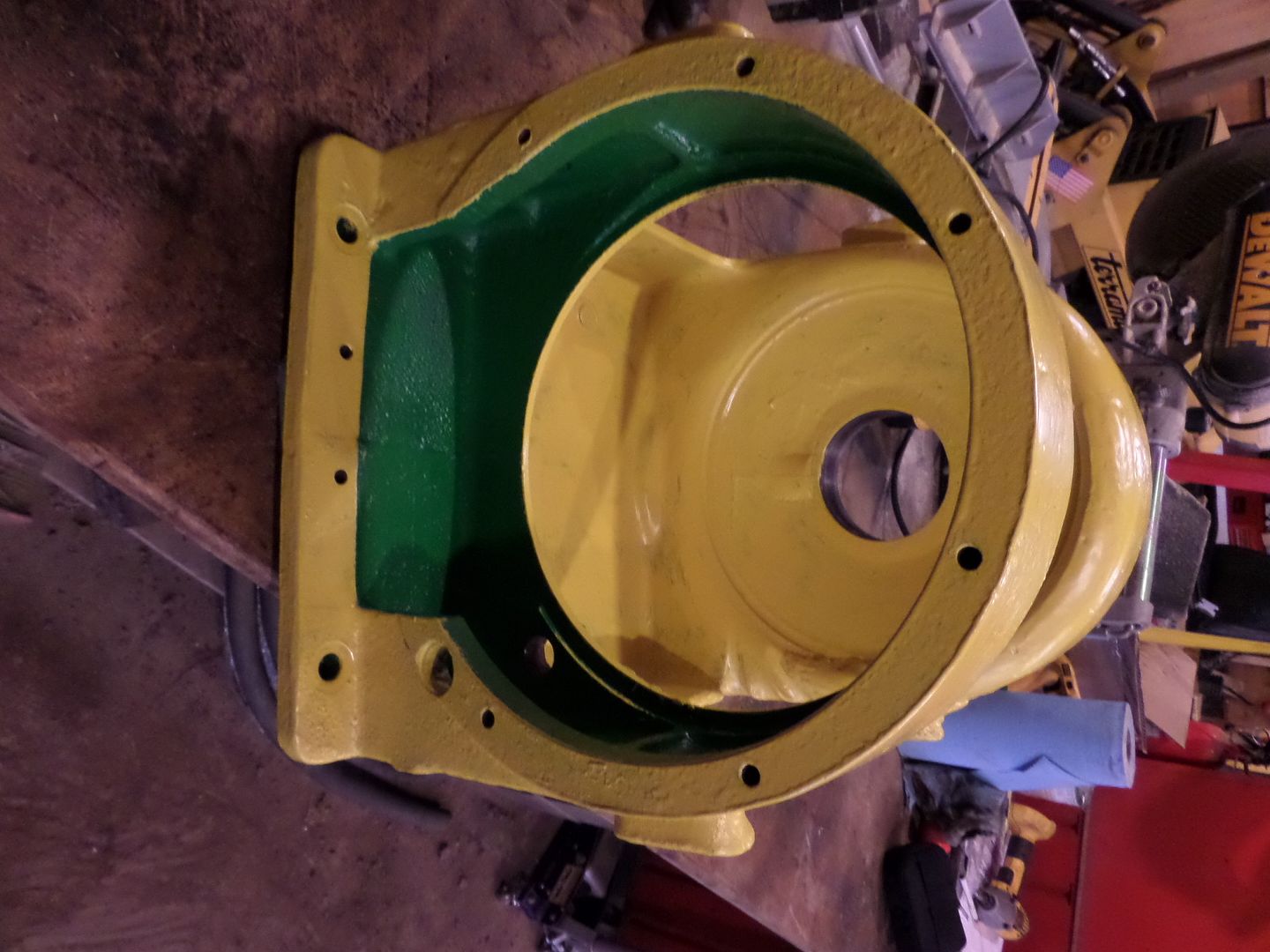

Bare winch drum with no internals. Never mind the paint colors, I was running low on yellow so I started using green for parts that will not be seen internally.

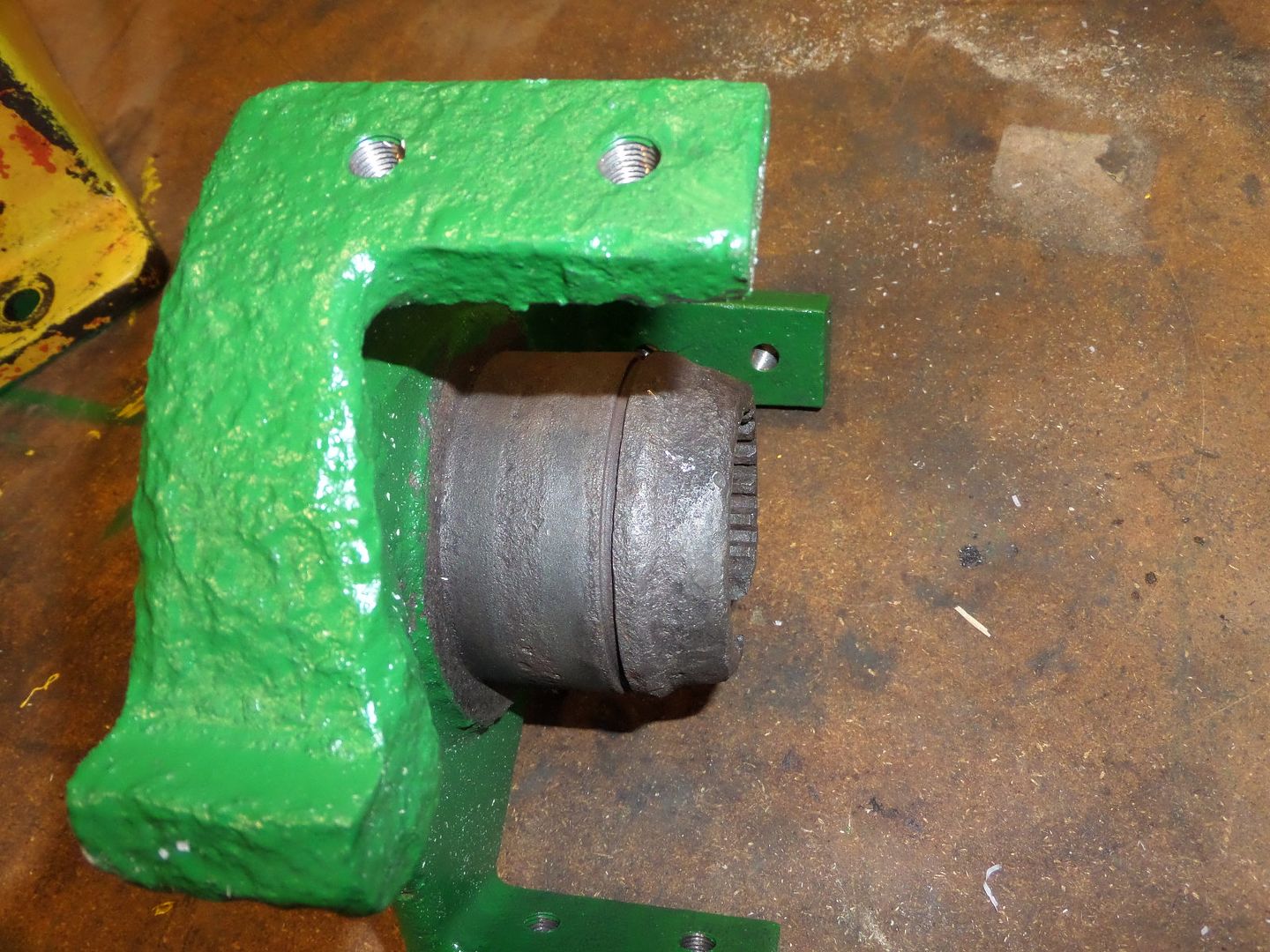

Winch mount all rebuilt and ready for the winch.

All of the bearings and seals I needed I crossed the old numbers for the newer part numbers and I purchased everything thru ebay as new old stock. The bearings I used are all NTN brand. I also had to enlarge most of the clutch adjustment holes to the next biggest size since all of the bolts were rusted solid. Up next relining the clutch and brake, the metals are still good and solid, I may use the clutch and brake lining from McMaster-Carr or I may have a professional do it. It does not seem hard to bond the lining to metal. Paul, the only thing that I can see that would give you better clutch adjustment is if there is a buildup of rust around the clutch bands. Which I did had a lot of... I hope this helps! A couple more photos here: http://www.jdcrawlers.com/messageboard/ ... hp?t=10293

Last edited by notmeu on Sun Oct 04, 2015 6:45 pm, edited 1 time in total.

1956 JD420, gearmatic 8a winch, custom 6 way blade and FOPS.

I am going to get a batch of winch parts made up again. In next couple weeks, I will have brake return springs, spring adjusting nuts, and the clutch fluid nipples done if all goes well. Looking at making the clutch slave cylinders too if not too outrageous.

Lavoy

Lavoy

Parts and restoration for antique and late model John Deere crawlers.

Owner and moderator www.jdcrawlers.com

Owner and moderator www.jdcrawlers.com

- Paul Buhler

- 350 crawler

- Posts: 991

- Joined: Wed May 21, 2008 6:25 pm

- Location: Killington, VT

Tom: Thanks for posting your winch pictures and explanations. In my case, I think that the splines on my spider are worn, which allows it and the clutch bands to skew somewhat, causing the clutch to grab at unexpected times. I've set the gap to .020 which seems to be helping with this problem. As stated earlier, this will be an "in the future" project. Your comments and pictures give me a better idea of what to expect. Best wishes as you complete your rebuild.

Anyone have any thoughts on how best to "shim" my splines if in fact my hypothesis is correct?

Tom, another thought: I drilled my clutch adjusting bolts with two holes running through adjacent faces. This allowed me to use the retaining pins as shown in the manual, and still tweak adjustments and know that they would stay in place.

Paul

Anyone have any thoughts on how best to "shim" my splines if in fact my hypothesis is correct?

Tom, another thought: I drilled my clutch adjusting bolts with two holes running through adjacent faces. This allowed me to use the retaining pins as shown in the manual, and still tweak adjustments and know that they would stay in place.

Paul

Paul Buhler

Killington, VT

420c 5 roll with 62 blade, FOPS, and Gearmatic 8a winch

Killington, VT

420c 5 roll with 62 blade, FOPS, and Gearmatic 8a winch

- RacinJason

- 430 crawler

- Posts: 72

- Joined: Wed Aug 29, 2012 6:41 am

- Location: Spfld, MA/ Corinth, ME

Spline Buildup

Paul, it's been a long time since I was a machinist, but I think a plating shop could build up the splined portion of the shaft. (Or Spider) May be cheaper to find another part.

JD 112, JD 420 C

Tom, another thought: I drilled my clutch adjusting bolts with two holes running through adjacent faces. This allowed me to use the retaining pins as shown in the manual, and still tweak adjustments and know that they would stay in place.

Paul[/quote]

Paul, I already have new bolts and a pin ready to slide thru the 2 bolts. I figured that I would mark the bolts and then drill the bolt heads once the correct position was achieved. My luck, if I would pre drill the bolts they would be at the wrong spot.

Paul[/quote]

Paul, I already have new bolts and a pin ready to slide thru the 2 bolts. I figured that I would mark the bolts and then drill the bolt heads once the correct position was achieved. My luck, if I would pre drill the bolts they would be at the wrong spot.

1956 JD420, gearmatic 8a winch, custom 6 way blade and FOPS.

- Paul Buhler

- 350 crawler

- Posts: 991

- Joined: Wed May 21, 2008 6:25 pm

- Location: Killington, VT

Sounds like a plan. My adjacent face drilling was the result of needing a larger gap in my clutches. I used never seize on the bolts since the metal removed compromises the bolt strength and without it, I'd probably twist a head off at some point in the future.

Paul Buhler

Killington, VT

420c 5 roll with 62 blade, FOPS, and Gearmatic 8a winch

Killington, VT

420c 5 roll with 62 blade, FOPS, and Gearmatic 8a winch

Paul, keep checking ebay and craigslist for a winch you may be surprised at what you find. 6 or so months ago I found a 8a that had all of the internals but it was in a very bad rusty shape like the above photo, and it didn't sell for the 100.00 starting bid. That's how I found the 2 winches I picked up to make one good one. I got them really cheap! It never hurts to have too many parts for these old girls!!!

1956 JD420, gearmatic 8a winch, custom 6 way blade and FOPS.

- Paul Buhler

- 350 crawler

- Posts: 991

- Joined: Wed May 21, 2008 6:25 pm

- Location: Killington, VT

Always on the search for good used parts. I've often found this effort more cost effective than other options. That said, I'm a hobby equipment user. When I needed to use my machines to pay the bills, I often chose the most time efficient solution.Paul, it's been a long time since I was a machinist, but I think a plating shop could build up the splined portion of the shaft. (Or Spider) May be cheaper to find another part.

Paul Buhler

Killington, VT

420c 5 roll with 62 blade, FOPS, and Gearmatic 8a winch

Killington, VT

420c 5 roll with 62 blade, FOPS, and Gearmatic 8a winch

Who is online

Users browsing this forum: No registered users and 55 guests