General help and support for your Lindeman through 2010 John Deere crawler

-

RogerW

- 40C crawler

- Posts: 13

- Joined: Thu Jun 10, 2010 11:32 am

Post

by RogerW » Sat Jun 19, 2010 6:06 pm

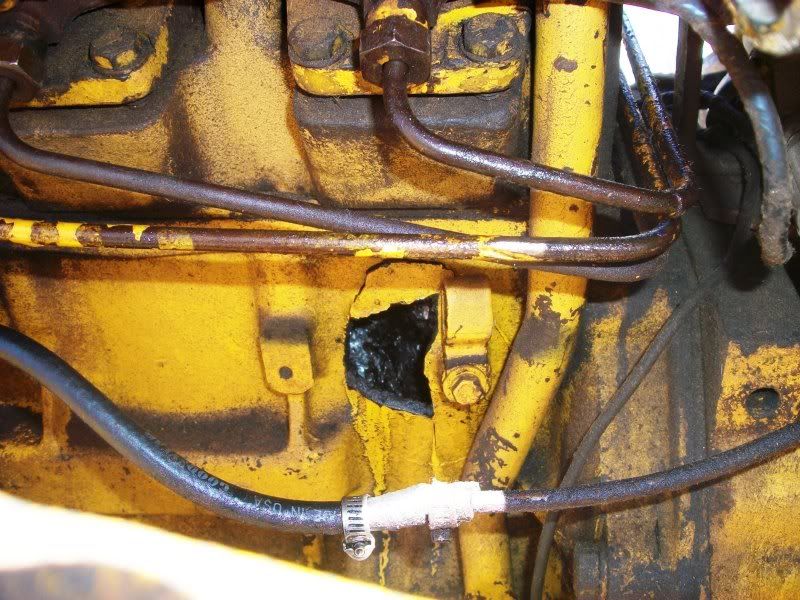

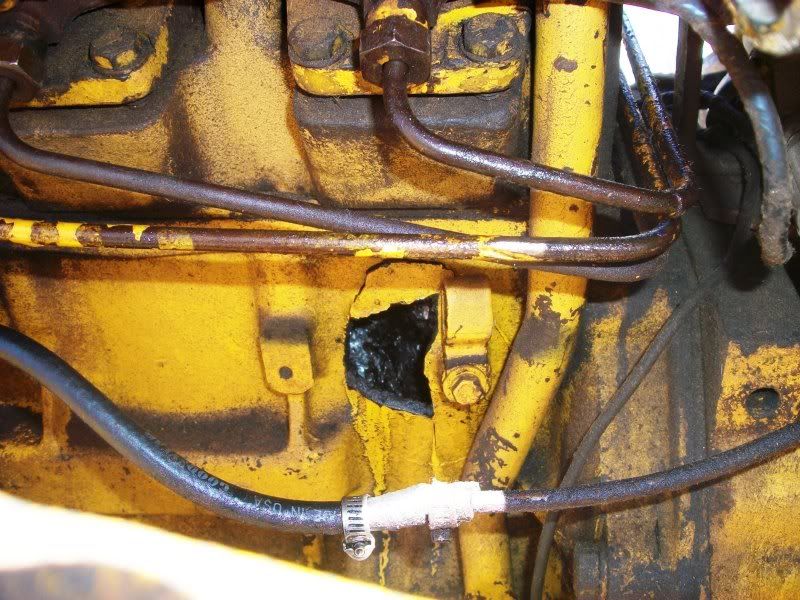

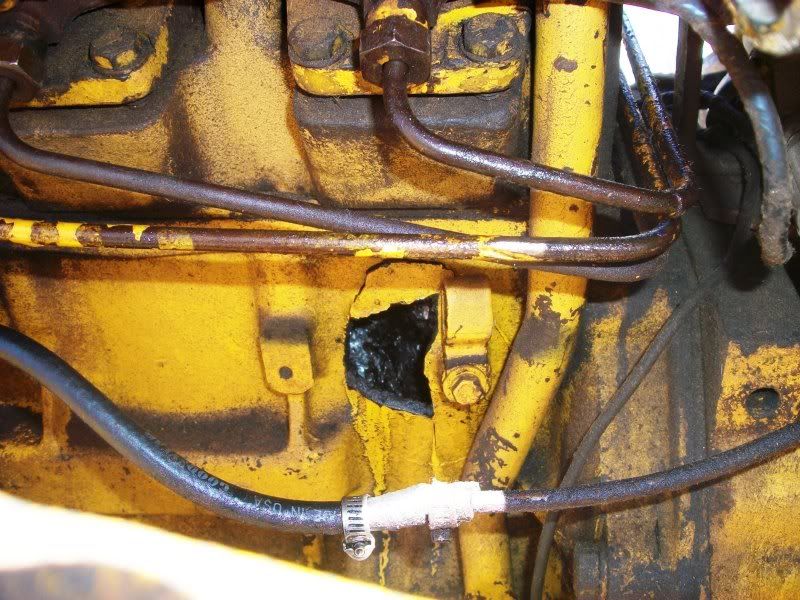

Got started evaluating my new to me 2010 diesel dozer project that I recently acquired. I knew it had some water in the oil issues but it would start. Drained oil and added fresh. I would not let it run for no longer than two minutes as I knew something wasn't quite right. Well that something turned into an extra hole in the block. Motor went from sounding reasonably O.K to boat anchor in seconds. I had planned on a rebuild anyway but I wanted to evaluate the blade and steering clutches while it ran. Bad idea!

I have only had the dozer for one day and this happens.

Now I need a usable 2010 block and rebuild parts or perhaps someone has a good used complete 2010 diesel motor.

-

Lavoy

- Site Admin

- Posts: 11148

- Joined: Sun Apr 03, 2005 8:32 pm

- Location: North Dakota

-

Contact:

Post

by Lavoy » Sat Jun 19, 2010 10:38 pm

Call Pete's tractor salvage at Anamoose just in case. If not, maybe Meyer brothers in Aberdeen.

Lavoy

-

jdman

- 430 crawler

- Posts: 54

- Joined: Tue Apr 05, 2005 1:09 pm

- Location: Chesaning, Michigan

Post

by jdman » Mon Jun 21, 2010 10:49 am

What Caused The Hole???

Aweful High On The Block For The Rod ???

Rod Would Have Had To Go Threw The Sleeve Assy. First...

JEff

-

JD440ICD2006

- 350 crawler

- Posts: 1113

- Joined: Tue Aug 22, 2006 3:57 pm

- Location: South Carolina

Post

by JD440ICD2006 » Mon Jun 21, 2010 10:56 am

May be possible to weld it back. A place named "MUGGY WELD" sells special rods of materials that will do it.

I am curious too as to what made the hole.

1959 JD 440ICD w/64 Power Angle Tilt Blade

1959 JD 440ICD w/63 Manual Angle Blade

1959 JD 440IC w/602 Manual Angle Blade

1959 JD 730D W SE (many options)

1950 JD M S w/M-20 Mower

1952 JD M W

1955 FORD 640 (burns the most fuel)

-

JD430C

- 1010 crawler

- Posts: 350

- Joined: Tue May 03, 2005 11:00 pm

- Location: Northfield, Vermont

-

Contact:

Post

by JD430C » Mon Jun 21, 2010 11:44 am

Hi, I am going to guess the same thing happened to it that happened to my 2010. The rod bolts came out and the crank bumped the rod into the block. Mine did it on No 2 around the same height on the block. If you have the piece I would send the block out to check for other cracks. IF its fine I would weld it back up. I would have on mine if I had the piece. Its gonna be hard to find a crack free 2010 diesel block.

Andrew

jds- 450B, 450C, 550, 4020, 3140 MFWD, 5200 MFWD

-

claude murwin

- 420 crawler

- Posts: 27

- Joined: Thu Apr 23, 2009 6:02 pm

- Location: otego, ny

Post

by claude murwin » Mon Jun 21, 2010 7:58 pm

Is the block the same as a 2010 wheel tractor? might have one

1010 dozer,750,dozer,2010 tractor,ac d17,vac case

-

Tiny Crawler

- 430 crawler

- Posts: 97

- Joined: Sun Jan 22, 2006 4:24 pm

- Location: Binghamton

Post

by Tiny Crawler » Tue Jun 22, 2010 4:14 pm

You can try this stuff, if it isn't in a critical area, I got a boat from a guy that didn't winterize and the water jacket cracked, tried welding but the crack kept going, talked to the mechanic at the local marina and he suggested this stuff, it is like steal. and it sealed the outside of the block.

http://www.marinetex.com/marinetexepoxyputty.html

-

Tigerhaze

- 350 crawler

- Posts: 2278

- Joined: Thu Jul 06, 2006 12:13 pm

- Location: West-Central MO

Post

by Tigerhaze » Wed Jun 23, 2010 11:34 am

claude murwin wrote:Is the block the same as a 2010 wheel tractor? might have one

I believe the crawlers and wheel tractors use the same blocks, as long as you are comparing like fuel types (i.e. diesel to diesel).

(1) JD Straight 450 crawler dozer with manual outside blade; (2) JD 2010 diesel crawler loaders; (1) JD 2010 diesel dozer with hydraulic 6-way blade; (2) Model 50 backhoe attachments, misc. other construction equipment

-

Lavoy

- Site Admin

- Posts: 11148

- Joined: Sun Apr 03, 2005 8:32 pm

- Location: North Dakota

-

Contact:

Post

by Lavoy » Wed Jun 23, 2010 9:02 pm

One of the members on here and I just had a discussion about this. Tractor parts manual shows at least 3 different block depending on serial number, crawler shows one regardless of serial number. Doesn't mean they won't work, but by application, there is a difference.

Lavoy

-

fletcher

- MC crawler

- Posts: 6

- Joined: Wed Jul 07, 2010 8:43 pm

- Location: madison nc

Post

by fletcher » Thu Jul 08, 2010 7:02 pm

308 stainless rods work good on cast and are cheaper than cast rods. Be sure to preheat.

-

H-D

- 430 crawler

- Posts: 82

- Joined: Sun Nov 25, 2007 11:23 pm

- Location: NW TN

Post

by H-D » Thu Jul 08, 2010 11:09 pm

Don't you have to drill the ends of the cracks to keep them from running? Been a LONG time since I had any exposure to a welded block. Back then I remember the pre-heating (about 2" at a time) was critical & seems like the rod was nickel?

-

fletcher

- MC crawler

- Posts: 6

- Joined: Wed Jul 07, 2010 8:43 pm

- Location: madison nc

Post

by fletcher » Thu Jul 08, 2010 11:48 pm

yes I recomend drilling. Your 308 stainless will get you the high nickel. On your preheat Heating out 2" from your weld will also relieve some of the stress you put on it. I like to post heat as well. The slower you let it cool the better.

-

H-D

- 430 crawler

- Posts: 82

- Joined: Sun Nov 25, 2007 11:23 pm

- Location: NW TN

Post

by H-D » Fri Jul 09, 2010 7:21 pm

Thank you fletcher The ol' minds not totally gone, just circling the drain.

-

Stretch

- 440 crawler

- Posts: 200

- Joined: Mon Feb 19, 2007 6:48 pm

- Location: Albemarle, NC

Post

by Stretch » Sat Jul 10, 2010 6:14 pm

I have a good block if you're interested.

Stretch

2010C Dozer, 2010C Loader

If at first you don't succeed, get a bigger hammer.

Who is online

Users browsing this forum: No registered users and 14 guests