First thing, I installed the cam bearings with a homemade tool. The bearing driver consists of 2 pieces of 1" coarse threaded rod, 3 hex nuts, and 2 homemade drivers.

The drivers are just big heavy washers. One is 2" diameter with a 1-1/16" hole drilled in the center and about 1" thick. The bearing driver is 1.925" diameter with a 1-1/16" hole in the center and also about 1" thick. I used a lathe to make them.

I used 2 pieces of 1" coarse threaded rod because I had them. They are 14" and 24" long. You can get away with just the 24" one, but it was easier to align the tool for the middle and front bearing with the 14" chunk.

To remove the front bearing, lock 2 nuts together on one end leaving 1" of thread protruding (1" is the thickness of the driver washer I made). Take the third nut and thread it on the other end of the rod to protect the threads. Now use this assembly and a hammer to drive the front cam bearing into the block.

To remove the middle and rear cam bearings use the threaded rod, driver washer, large washer and 2 nuts to pull the bearings out the front of the bosses. Take your time and check alignment by feel. They should come out relatively easily, so if you have to use excessive force, check your alignment.

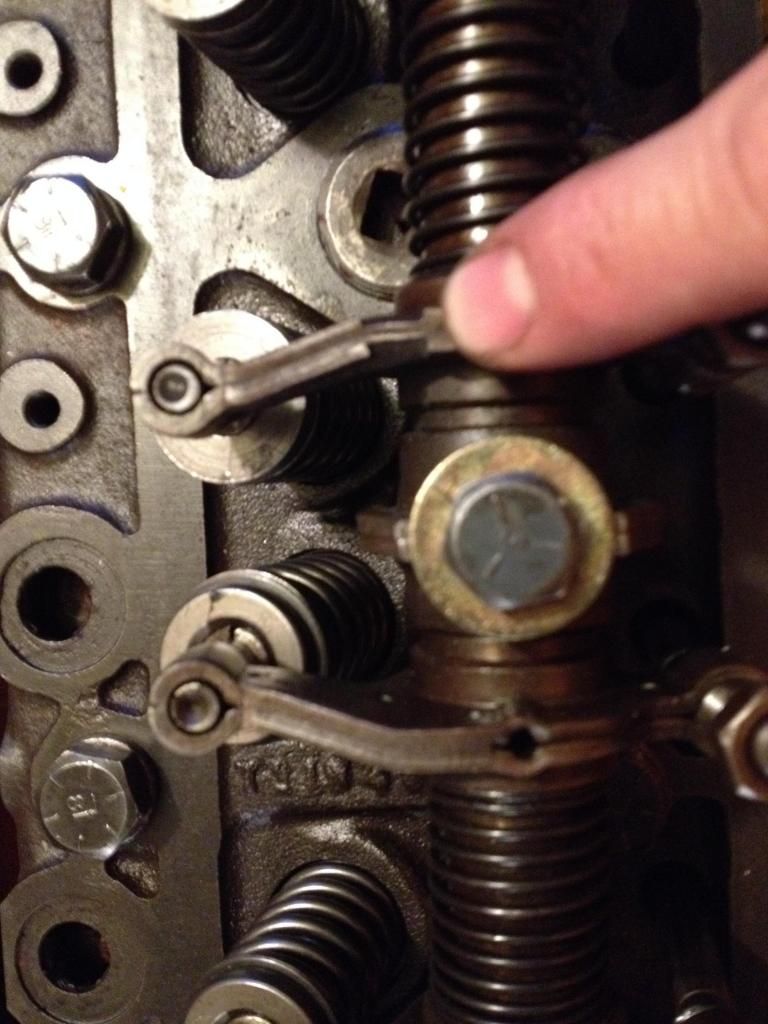

To install the new cam bearings, use the driver washer, 2 nuts, appropriate threaded rod length and the large washer to pull the bearings into place from rear to front. Use electrical tape on the threads where the bearing is to protect the very soft bearings from accidental contact with the sharp threads of the rod. Install the bearings rear first (pull it until it is flush with the front of the bore), then middle (centered in bore), and then the front one (centered in bore). Use a Sharpie marker to mark the location of the oil holes to aid in alignment with the holes in the bearings. The front and rear bearings are very forgiving with alignment, but the center one is a bugger. Note that the front bearing is wider than the other two and the oil hole is NOT on center.

Next, clean up the tappets and install them. Make sure they slide up and down in their bores easily. Oil everything.

I cleaned up the lobes on the cam with Scotch Brite. I had to push gear onto the camshaft with a hydraulic press to compensate for wear in the thrust plate. Reference the service manual for specs. I then greased the bearing surfaces and cam lobes and oiled the bearings. Carefully install the camshaft slowly so as not to drag the sharp lobe edges across the soft bearings.

I measured the bearing surfaces on the camshaft and the bores of the new cam bearings before installation and was concerned with the relatively large tolerances. Because of wear, they were a bit on the loose side dimensionally. I was surprised how much the cam bearings shrunk after being installed. In the end, the cam slipped in with slight difficulty because of this shrinkage and resulting reduction in bearing tolerance. Everything went together with high precision and the cam rotates with no perceptable play whatsoever.

[/img]

[/img]

[/img]

[/img]

[/img]

[/img]

[/img]

[/img]

[/img]

[/img]